ZG42CrMo's specialized stainless steel sleeve

Sleeve is widely used in aluminum and copper sheet and strip. Therefore, our company has a strict quality control requirement in production and inspection process.

************************** Advantage of GW Precision steel spool **************************

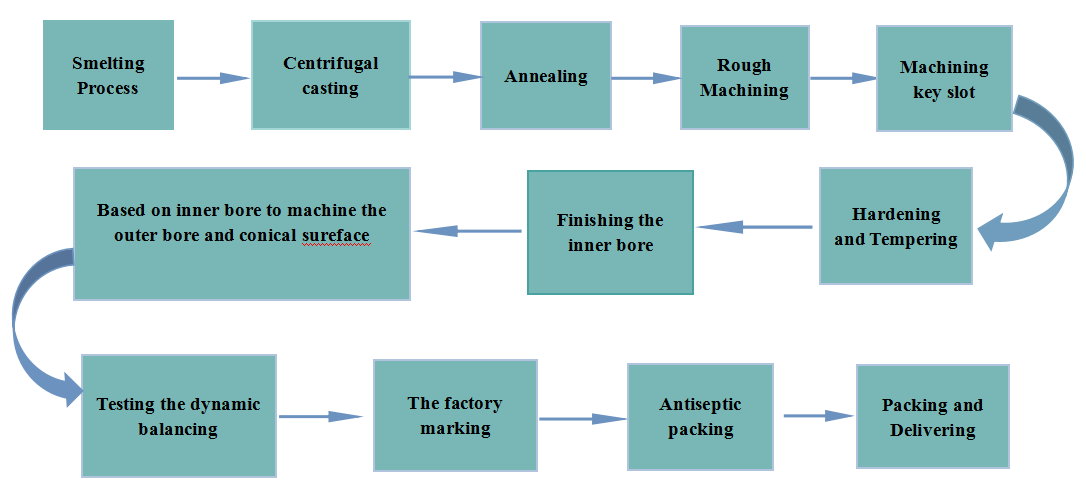

1、The steel sleeve blank of GW Precision is obtained by centrifugal casting.

2、Our company has a well-developed management system. Meanwhile, our employees are highly qualified and skilled.

3、GW Precision annual production capacity of the steel sleeve is 4000 sets per year.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

ZG42CrMo's specialized stainless steel sleeve

| Sleeve Material | Specification |

| ZG42CrMo | 355*305*1300 |

ZG42CrMo is a high-strength alloy cast steel that combines the excellent mechanical properties of 42CrMo with the forming advantages of cast steel. It is suitable for sleeve components with high load, high wear resistance, and corrosion resistance.

Chemical composition of ZG42CrMo (mass percentage)

Execution standard: Refer to GB/T 3077-2015 (Alloy Structural Steel) and Casting Process Adjustment

Range of Element Content (%) Function

Carbon (C) 0.38-0.45 dominates hardness and strength, forming a carbide strengthening phase

Chromium (Cr) 0.90-1.20 improves hardenability, corrosion resistance, and high-temperature strength

Molybdenum (Mo) 0.15-0.25 suppresses temper brittleness and enhances creep resistance

Manganese (Mn) 0.50-0.80 improves hardenability and assists in deoxidation

Silicon (Si) 0.17-0.37 deoxidation enhances strength

Phosphorus (P) ≤ 0.035 impurities (strictly controlled)

Sulfur (S) ≤ 0.035 impurities (affecting thermal brittleness)

Heat treatment process of ZG42CrMo special stainless steel sleeve

(1) Annealing (eliminating casting stress)

Process: 860~890 ℃ × 4~6h, furnace cooled to 500 ℃ and then air cooled;

Objective: To achieve uniform organization and improve machinability.

(2) Quenching+tempering (quenching and tempering treatment)

Quenching: Oil quenching at 850~880 ℃ (for small and medium-sized parts) or water quenching (for large parts);

Tempering:

High temperature tempering (high toughness): 600~650 ℃ × 2h, hardness HRC 25~30;

Medium temperature tempering (balance performance): 500~550 ℃ × 3h, hardness HRC 30~35.

(3) Surface strengthening (optional)

Laser cladding: surface cladding with Stellite 6 or WC Co coating (wear-resistant and corrosion-resistant);

Plasma nitriding: surface hardness ≥ HV 1000, depth 0.2~0.4mm.

Description of heat treatment of stainless steel sleeve

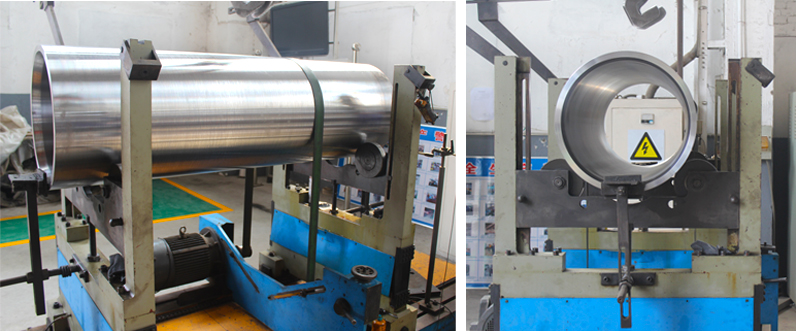

GW precision used independent dedicated device-hole drilling machine which is researched and developed by ourselves, it also obtain the national patent. The machine is provided with good rigid, no returning clamp and machine and high accuracy on the processing of machining. Through continuous improvement, our company formed a integrated processing technic system to ensure concentricity, cylindricity, degree of symmetry and dynamic balance of the steel sleeve. Specific accuracy tolerance and geometric accuracy tolerance is strictly according to the customers’ requires.

Dynamic balancing test

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of stainless steel sleeves, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.