Customized 35CrMoV Steel Spool Of Aluminum Foil

Application:Sleeve is widely used in aluminum and copper foil, plate and belt.

Advantage of GW Precision spool:

1、GW Precision has our own professional processing of the design, develop, manufacture and sales.

2、Our company has a well-developed management system. Meanwhile, our employees are highly qualified and skilled.

5、The company has a perfect management system of the guarantee of the after-sales service.

6、Our customers are already spread all over China, and our annual production capacity of the sleeve is 4000 sets per year.

- GW Precision

- Henan,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized 35CrMoV Steel Spool Of Aluminum Foil

Main Product:stainless steel sleeve

Product Information:

| Sleeve | Specification |

| 35CrMoV | 665*605*1900 |

Application scenario of aluminum foil customized 35CrMoV steel sleeve

In the aluminum foil mill, 35CrMoV steel sleeve is mainly used for the following key parts:

Roll bearing sleeve

Support the high speed rotating mill roll, bear the radial and axial load, and require high rigidity and fatigue resistance.

Drive connection sleeve

High torsional strength and abrasion resistance are required to transfer rolling torque to avoid abrasion caused by micro-slip.

Guide and positioning sleeve

Ensure foil rolling thickness uniformity (tolerance ± 0.001mm) and reduce vibration and unbalance load.

Special requirements:

The aluminum foil rolling force is low, but the rotating speed is high (up to 2000m/min), and the sleeve needs to have excellent anti-fretting performance.

High surface finish requirements (Ra ≤ 0.4 μ m) to avoid scratches on the aluminum foil surface.

Through precision forging + tempering + nitriding + ultra-fine machining, 35CrMoV steel sleeve can meet the strict requirements of aluminum foil mill for high speed, low friction and ultra-high precision. The core lies in surface modification technologies (e.g. nitriding or coating) and micron level machining accuracy control to extend service life and ensure foil surface quality.

Description of heat treatment of steel sleeve:

GW Precision will conduct heat treatment strictly for Customized 35CrMoV Steel Spool Of Aluminum Foil which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every Customized 35CrMoV Steel Spool Of Aluminum Foil to achieve the best condition and customers good results.

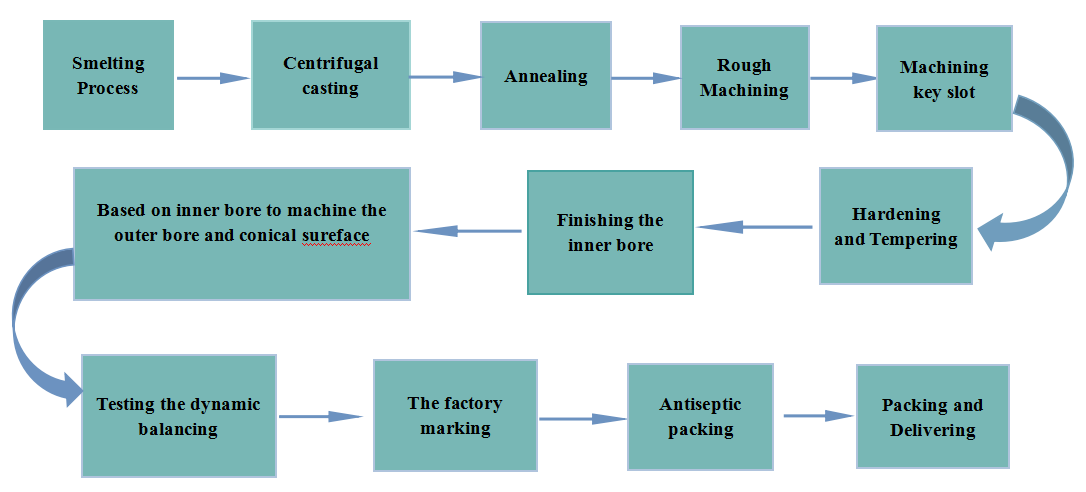

(production process)

The workblank of spools will be processing on the hole drilling machine, which was developed by GW Precision. In the boring machine, the customized 35CrMoV steel spool blank can be adjusted to concentric of both the front and rear ends of the aperture, so as to achieve smooth cutting and improve machining accuracy. In the cutting process, the customized 35CrMoV steel spool is fixed without rotating, and the way that tool shaft rotates to cut the inner hole avoid the error of taper or other shapes. Smooth chip removal during the cutting process allowsto improve the surface smoothness and not easy to scratch the processed surface.

Packaging

The packaging must ensure the safety of the customized 35CrMoV steel spool , so that they will not be lost or damaged during storage and transportation.

Packing ensures product cleanliness. Confirm the cleanliness of product surface before packing.