Casting Steel Spool Of Copper Mill Machine

Application:GW precision Casting Steel Spool is widely used in aluminum foil, aluminum plate, stainless steel foil belt and other industries of foil, plate, tape rolling.

.

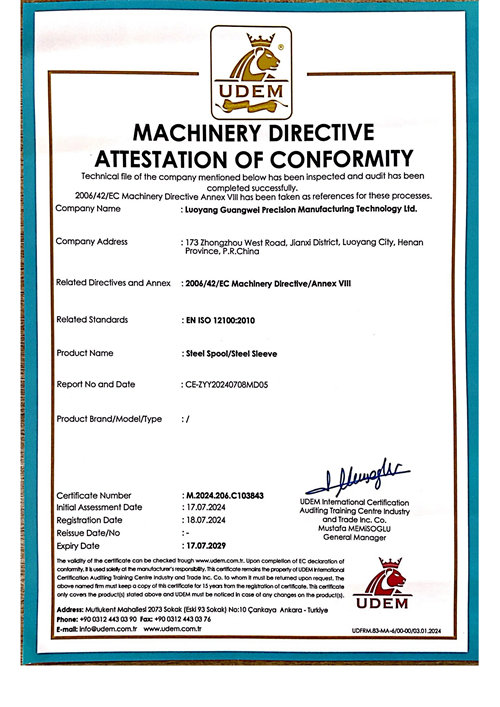

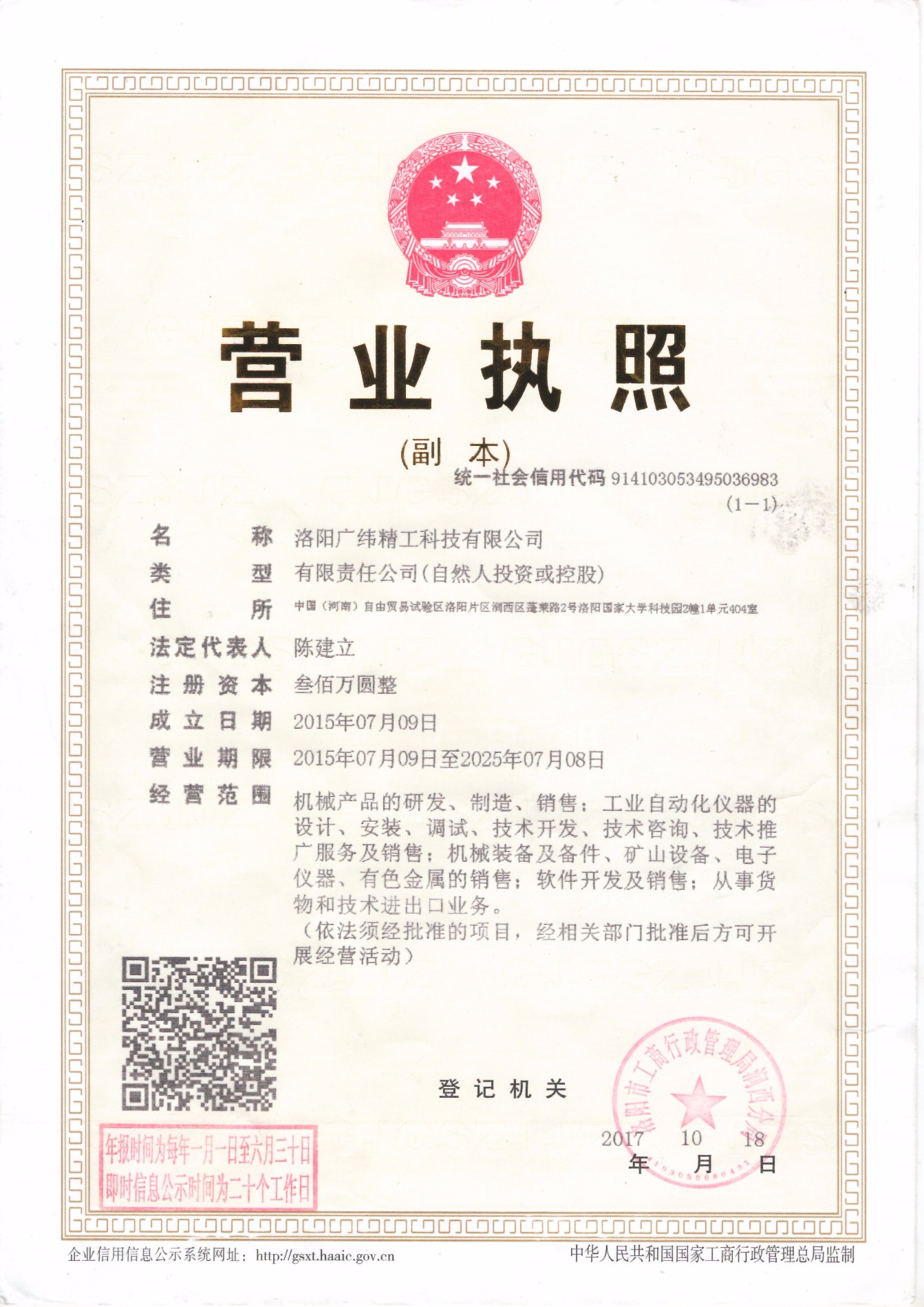

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Casting Steel Spool Of Copper Mill Machine

Main Product:stainless steel sleeve、casting steel spool

Product Information:

Sleeve Material | Specification |

35CrMoV | 665*605*2000 |

The 35CrMoV cast steel sleeve in copper rolling mill is a key component with high strength and wear resistance, which is mainly used in high temperature and high load rolling environment.

Application Scenario of 35CrMoV Cast Steel Sleeve for Copper Mill

Hot rolling of copper and copper alloy

Roll bearing sleeve for roughing and finishing mill stand, bearing high temperature (400-800 ℃) and high pressure load.

High abrasion resistance, resistance to adhesion wear and thermal fatigue of copper.

Rolling of other non-ferrous metals

Such as aluminum and magnesium alloy rolling mill, but the material composition or heat treatment process shall be adjusted according to the specific working condition.

Extreme operating condition

It is applicable to the rolling mill with frequent start-stop and large impact load. The strength and toughness of 35CrMoV can reduce the cracking risk.

Heat Treatment Process of 35CrMoV Cast Steel Sleeve for Copper Mill

Quenching and tempering (quenching+high temperature tempering)

Quench: Heat to 860-880 ℃ (austenitization), oil or water quench to obtain martensite.

Tempering: 550-650 ℃, heat preservation for 2-4 hours, air cooling, carbide precipitation, balance strength and toughness (target hardness HRC 28-35).

STRESS RELIEF ANNEALING (OPTIONAL)

Heat to 600 ° C after rough machining and slow cool to eliminate casting and machining residual stresses.

Surface strengthening (as required)

Nitriding or high-frequency quenching improves the surface abrasion resistance (such as depth of nitriding layer 0.2-0.5mm, hardness ≥ HV 800).Key Control Points of 35CrMoV Cast Steel Sleeve for Copper Mill

Component segregation: Element V needs to be evenly distributed to avoid local embrittlement.

Cooling rate: avoid cracks caused by too fast quenching (especially for sleeve with large section).

Residual stress: before finishing, the stress shall be fully relieved to prevent deformation.

By optimizing heat treatment and manufacturing process, 35CrMoV sleeve can achieve 5-10 years of service life in copper rolling mill, significantly better than ordinary carbon steel sleeve.

GW Precision adopts advanced smelting and casting technology, with the equipment has accurate inspection to ensure the chemical composition of the sleeve material is reliable and accurate. Centrifugal casting is adopted to guarantee the inner and outer surface of the sleeve is free from defects such as cracks, slag inclusion, pores and sand holes.

Guangwei Precision Technology Co.,Ltd is ready to support you for any casting steel spool repair needs you may have.

guangwei@gwspool.com or +86-379-64593276