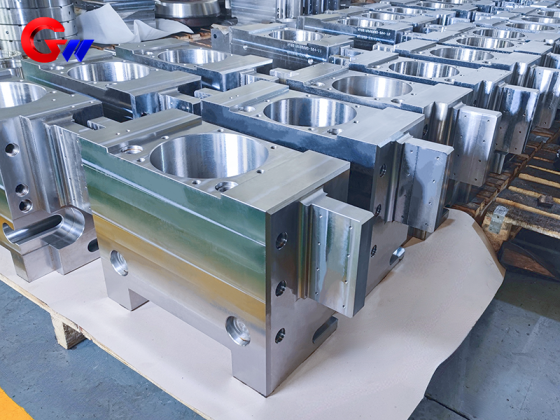

Casting Steel Work Roller Bearing Block

GW precison have the following key products:

1. Casting steel work roller bearing block

2. Steel sleeves for non-ferrous metal sheet and strip

3.Precision mechanical spare parts

4.Customized complete sets of equipment and other mechanical products

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Information

Casting Steel Work Roller Bearing Block

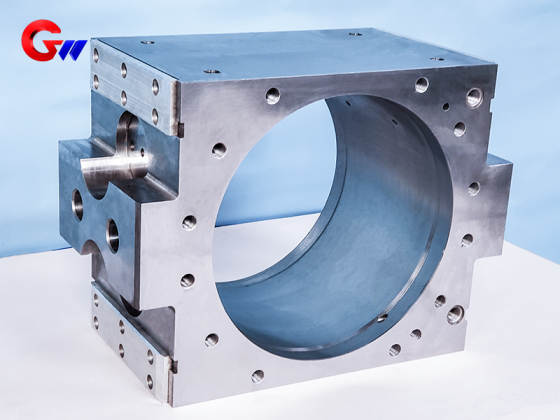

The use function of cast steel work roll bearing seat

The cast steel work roll bearing seat is the core load-bearing component of the rolling mill, and its main functions include:

Support and positioning

Carrying work rolls and rolling forces (up to thousands of tons) to ensure stable rotation of the rolls.

Maintain the coaxiality between the rolling mill and the frame (≤ 0.02mm) to prevent the rolling strip from deviating.

Force transmission and buffering

Transfer the rolling force to the frame while absorbing the rolling impact (such as the dynamic load at the moment of steel biting).

Sealing and lubrication management

Built in sealing structure (such as labyrinth seal+rubber lip seal) prevents the intrusion of cooling water and iron oxide scale.

Provide stable lubrication (thin oil circulation or lithium grease lubrication).

High temperature resistance and wear resistance

Maintain dimensional stability under hot rolling conditions (200-600 ℃), and the bearing mating surface should be wear-resistant (hardness ≥ HRC50).

Material selection of cast steel work roll bearing seat

Common materials

Low alloy high-strength cast steel (mainstream choice):

ZG35CrMo (tensile strength ≥ 650MPa after quenching and tempering, fatigue resistance).

ZG42CrMo (higher load, used for heavy-duty rolling mills).

ZG30CrNiMo (excellent low-temperature impact toughness, suitable for cold regions).

Special working condition materials:

ZG1Cr18Ni9Ti (corrosion-resistant, used in high humidity or acidic/alkaline environments).

ZG20CrMoV (high-temperature rolling mill, strength retention rate ≥ 80% at 500 ℃).

Material modification requirements

Surface quenching: High frequency quenching of bearing mating surfaces (hardness HRC50-55, layer depth 2-3mm).

Alloy optimization: Add V and Nb microalloying to refine grain size (grain size ≥ ASTM grade 6).

Surface protection and assembly of cast steel work roll bearing seat

Rust prevention treatment:

Phosphating+rust proof oil (salt spray test ≥ 72h).

Assembly verification:

Simulated loading test (1.2 times rated load, continuous for 24 hours without plastic deformation).

As one of our key product, GW precision work roller bearing block have served for many customer from domestic and abroad . Our technicians are extremely experiences and are some of the best in the industry.

Base on the work conditions, our bearing blocks are used for different rolling mills:hot rolling mill , cold rolling mill and converted rolling mill, etc.

If you have technology questions, pls feel free to contact us.