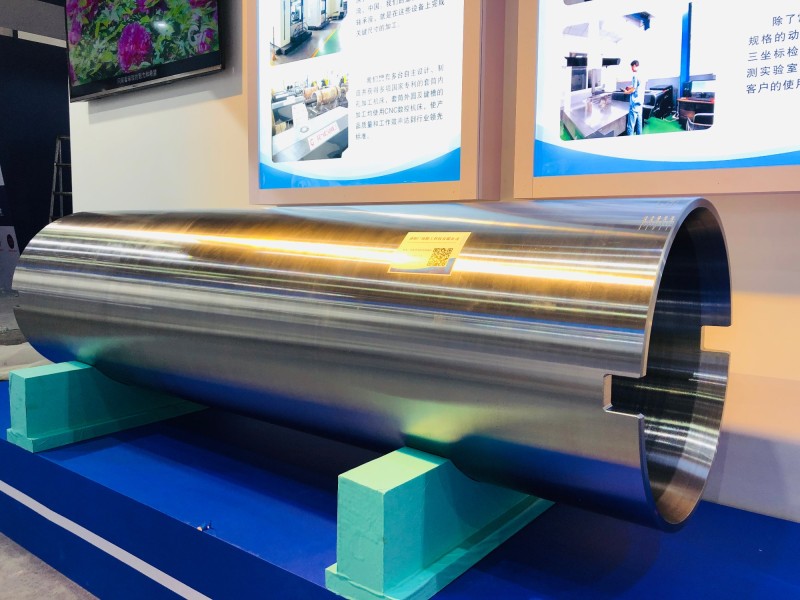

Tempered Customized Casting Steel Spool Of Cold Rolling Mill Machine

**********************************Advantage of GW spool**********************************

1、We has a strict requirement to concentricity of sleeve, dynamic balance and other requirements.

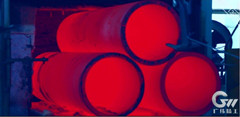

2、The steel sleeve blank of our company is obtained by centrifugal casting.

3、The company has our own professional processing of the design, develop and manufacture, also have proven machining technique.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Tempered Customized Casting Steel Spool Of Cold Rolling Mill Machine

Sleeve material | Specification |

35CrMoV | 565*505*1700 |

Application scenarios of customized 35CrMoV cast steel sleeve for cold rolling mill tempering

Core functions

Supporting rollers: withstand high radial pressure (up to hundreds of tons) and alternating loads during the cold rolling process;

Transmission torque: Drive the rolling mill to achieve high-precision rolling (strip thickness tolerance ± 1-3 μ m);

Fatigue and Wear Resistance: Suitable for high-speed rolling (300-800 rpm) and long-term cyclic stress.

Typical operating conditions

High load: The cold rolling mill has a large rolling force, and the sleeve needs to withstand extremely high contact stress;

Low temperature environment: Cold rolling temperature is usually ≤ 120 ℃, but local frictional heat can reach 200 ℃;

Lubrication requirements: Compatible with rolling oil to avoid corrosion and adhesive wear.

Applicable equipment

Four roll/six roll cold rolling mills (such as Sendzimir mills, UC-MILL);

High precision rolling mills (such as automotive sheet and tin plated sheet rolling units).

Mechanical properties of 35CrMoV (quenched and tempered: quenching+high-temperature tempering) steel sleeve

Typical value testing standards for performance indicators

Tensile strength (σ ₆) 900-1100 MPa GB/T 228.1 (ISO 6892)

Yield strength (σ ₀) ₂) 750–950 MPa

Elongation rate (δ) ≥ 12% with a gauge length of 5d (where d is the diameter of the specimen)

Impact energy (AKU) ≥ 50 J (at room temperature) GB/T 229 (ISO 148)

Hardness HRC 28-35 (quenched and tempered state) GB/T 230.1

Sectional shrinkage rate (ψ) ≥ 45%

Centrifugal casting steel spool is adopted by GW precision to guarantee the inner and outer surface of the sleeve is free from defects such as cracks, slag inclusion, pores and sand holes. Adopt mature heat treatment technology to ensure the mechanical properties of steel sleeve.

Description of heat treatment of steel sleeve

We will conduct heat treatment strictly for steel sleeve which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every product to achieve the best condition and customers’ good results.

For the inner hole processing of ultra-long steel sleeve, our company has developed and independently manufactured a special equipment -- variable speed self-feed deep hole boring machine;The machining of the outer circle is completed in the CNC lathe to ensure the dimensional accuracy of the outer circle of the sleeve.Through continuous improvement, our company has formed a set of perfect processing technology, to ensure the steel sleeve coaxiality cylindrical symmetry and dynamic balance and other technical indicators.