Inspected By Dynamice Balancing Test On Centrifugal Casting Steel Spool Of Sheet And Strip Mill Machine

GW Centrifugal Casting spool have the following advantages:

1. Our company is managed base on ISO 9001 quality management system .Meanwhile, our employees are highly qualified and skilled.

2. The company has the guarantee of the after-sales service.

3. Our company implements 6S management,(and) constantly improve the quality and skills of the staff, through the IE international quality system certification.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Inspected By Dynamice Balancing Test On Centrifugal Casting Steel Spool Of Sheet And Strip Mill Machine

Product Application

Centrifugal Casting Sleeve is widely used in bronze , stainless steel and aluminum foil,sheet and plate industry.

Product Information

| sleeve material | specification |

| CrMoV | 665*605*2000 |

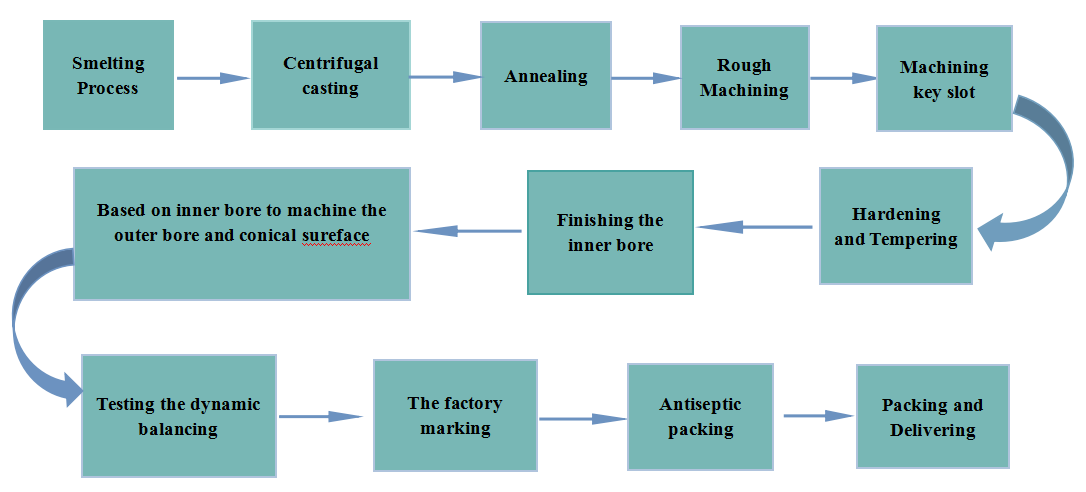

Production Process

Our company adopts advanced smelting and casting technology, centrifugal casting will ensure the chemical composition of the centrifugal casting sleeve material is reliable and accurate.

Description of heat treatment of centrifugal casting steel sleeve

GW precision will conduct heat treatment strictly for centrifugal casting steel sleeve which have the specific demand in mechanical property.

We used our independent dedicated device-hole drilling machine which is researched and developed by ourselves, it also obtain the national patent.

Material characteristics of CrMoV centrifugal cast steel sleeve customized for aluminum foil rolling mill

Performance index parameter advantages

Tensile strength ≥ 980 MPa, high bearing capacity

Yield strength ≥ 835 MPa, resistant to plastic deformation

Impact toughness ≥ 63 J (room temperature), resistant to high-frequency impact

Hardness (after quenching and tempering) HRC 32-38 (surface quenched HRC 45+) Excellent wear resistance

Heat resistance, long-term working temperature ≤ 300 ℃, suitable for aluminum foil rolling temperature rise

The role of key alloying elements:

Cr: Improve hardenability and corrosion resistance.

Mo: Inhibit high-temperature tempering brittleness.

V: Refine grain size and enhance toughness.

The CrMoV centrifugal cast steel sleeve of the aluminum foil rolling mill is achieved through three core processes: centrifugal casting, quenching and tempering heat treatment, and precision machining

High density (centrifugal casting porosity ≤ 0.5%);

Balance of strength and toughness (-20 ℃ impact toughness ≥ 40J);

Ultra precision fit (inner hole roundness ≤ 0.003mm).

Its customized design (such as intelligent monitoring and lightweight) can significantly improve the production efficiency and product yield of aluminum foil rolling mills.

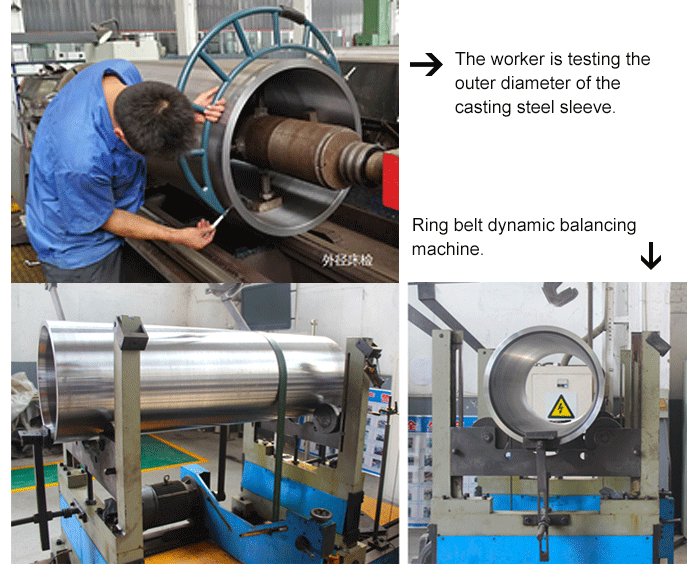

100% Dynamic Balancing Test for GW centrifugal casting sleeve

In order to safeguard the benefits of customers and ensure better quality of products.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

Product Packaging

The packaging must ensure the safety of the products, so that they will not be lost or damaged during storage and transportation.Confirm the cleanliness of product surface before packing.

For more technology information, pls feel free to contact us.

guangwei@gwspool.com or +86-379-64593276