Centrifugal cast steel sleeve for aluminum foil rolling mill detected by dynamic balance test

Application scenarios of centrifugal cast steel sleeve for aluminum foil rolling mill (dynamic balance test detection)

Core functions

High speed dynamic balance support: used as a roller support component in aluminum foil rolling mills (rolling speed ≥ 1000m/min) to ensure rotational stability (residual unbalance ≤ 0.5g · cm/kg).

Thermal expansion compensation: Reduce thermal deformation during high-speed rotation (Δ D ≤ 0.02mm@150 ° C).

Vibration suppression: Reduce high-frequency micro amplitude vibration (≤ 1 μ m amplitude) during rolling of thin foil (6-30 μ m).

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Centrifugal cast steel sleeve for aluminum foil rolling mill detected by dynamic balance test

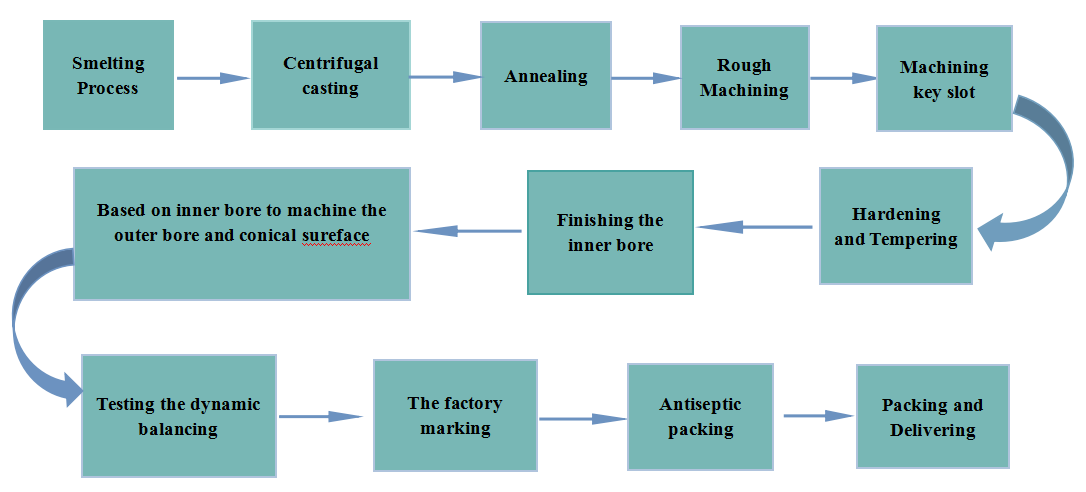

Material and Manufacturing Process of Centrifugal Cast Steel Sleeve for Aluminum Foil Rolling Mill (Dynamic Balance Test Detection)

Material: Centrifugal Casting ZG35CrMoV: C 0.30-0.38%, Cr 0.8-1.2%, Mo 0.2-0.4%, V 0.1-0.3% (Refined Grain)

Organizational characteristics: Centrifugal casting enriches impurities inward and makes the outer side dense without pores (density ≥ 7.85g/cm ³).

Heat treatment:

Normalizing+tempering (HB 220-250), ultra precision grinding of inner hole surface (Ra ≤ 0.4 μ m).

GW centrifugal cast steel sleeve is widely used in aluminum foil, aluminum plate, stainless steel foil belt and other industries of foil, plate, tape rolling.

sleeve material | specification |

35NiCrMo | φ565*φ505*φ1700 |

Advantages analysis of centrifugal cast steel sleeve for aluminum foil rolling mill (dynamic balance test detection)

High speed stability

Centrifugal casting eliminates segregation and has better dynamic balance performance than sand casting sleeves (reducing vibration by 50%).

LONG SERVICE LIFE

The dense outer layer is wear-resistant and has a lifespan of 6-8 years (ordinary cast steel sleeves only have 3-5 years).

Small thermal deformation

Uniform organization improves the consistency of thermal expansion coefficient, and the high-speed temperature rise Δ T ≤ 15 ° C

.

Description of heat treatment of steel sleeve

We will conduct heat treatment strictly for steel sleeve which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every product to achieve the best condition and customers’ good results.

We used our independent dedicated device-hole drilling machine which is researched and developed by ourselves, it also obtain the national patent. The machine is provided with good rigid, no returning clamp and machine and high accuracy on the processing of machining. Through continuous improvement, our company formed a integrated processing technic system to ensure concentricity, cylindricity, degree of symmetry and dynamic balance of the sleeve. Specific accuracy tolerance and geometric accuracy tolerance is strictly according to the customers’ requires.

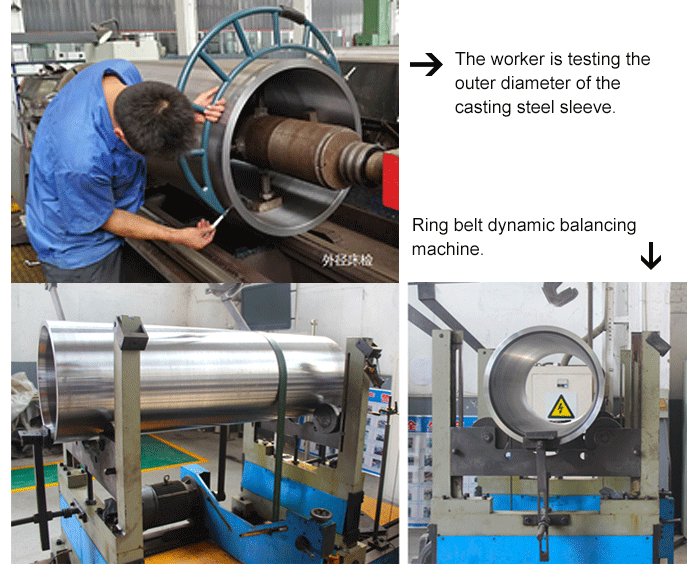

Dynamic Balancing Test

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.