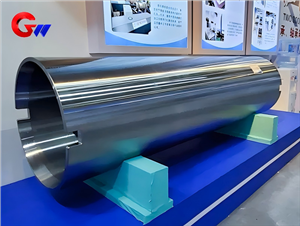

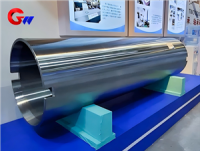

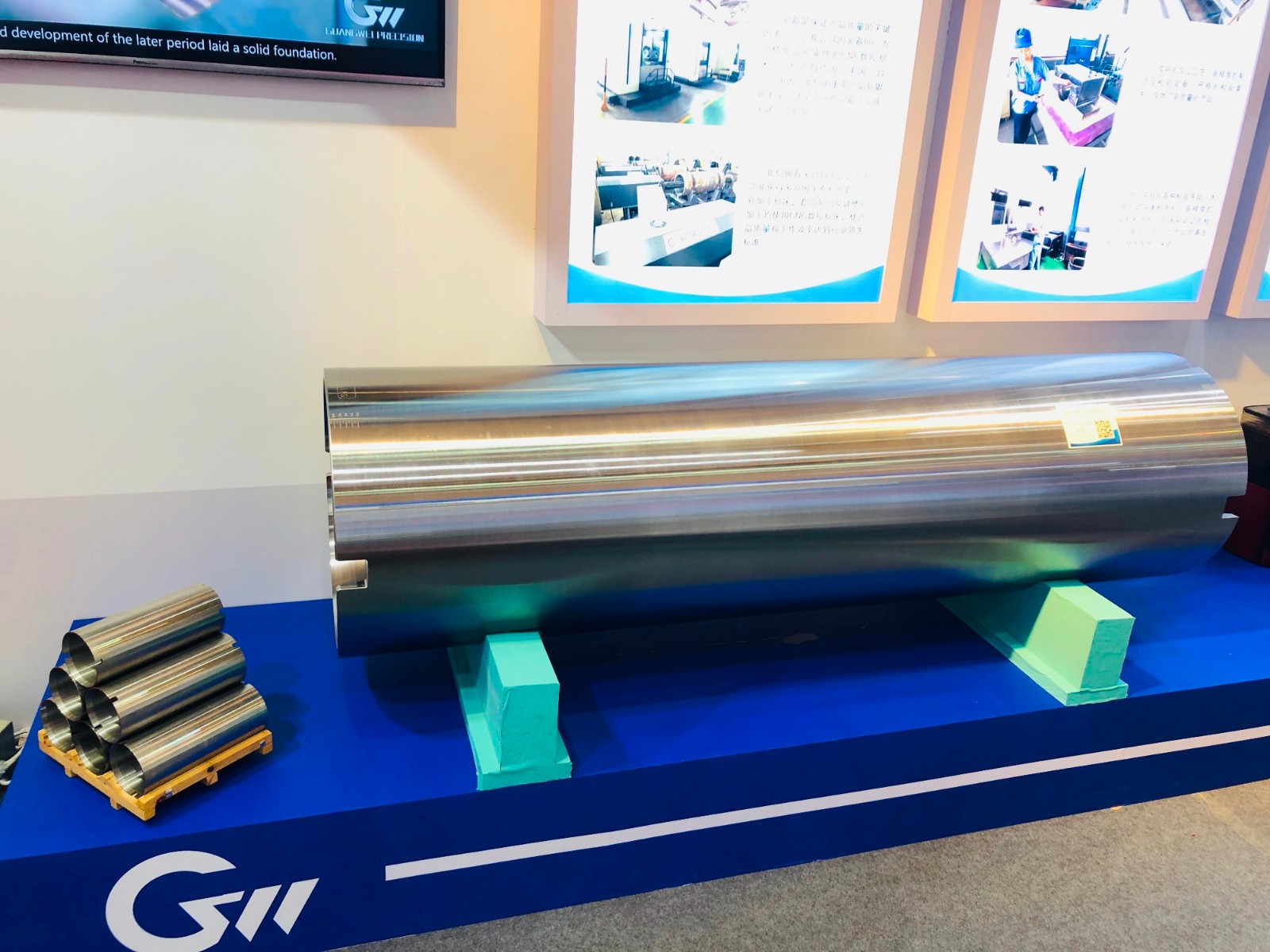

35CrMoV Cold rolling mill cast steel sleeve (dynamic balance test detection)

GW precision casting steel reel is an ideal choice for high-precision and high load conditions of cold rolling mills, especially suitable for thin strip rolling with strict requirements for dynamic balance. Its high strength, wear resistance, and cost-effectiveness advantages are obvious, but strict control of casting and heat treatment processes is required.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Inspected By Dynamice Balancing Test On Casting Steel Reel Of Cold Mill Machine

| Sleeve Material | Specification |

| 35CrMoV | Φ572*Φ506*2337 |

Chemical composition control (key elements):

Element C Si Mn Cr Mo V P ≤ S ≤

Range 0.30~0.38 0.20~0.40 0.50~0.80 0.90~1.20 0.20~0.30 0.10~0.20 0.025 0.025

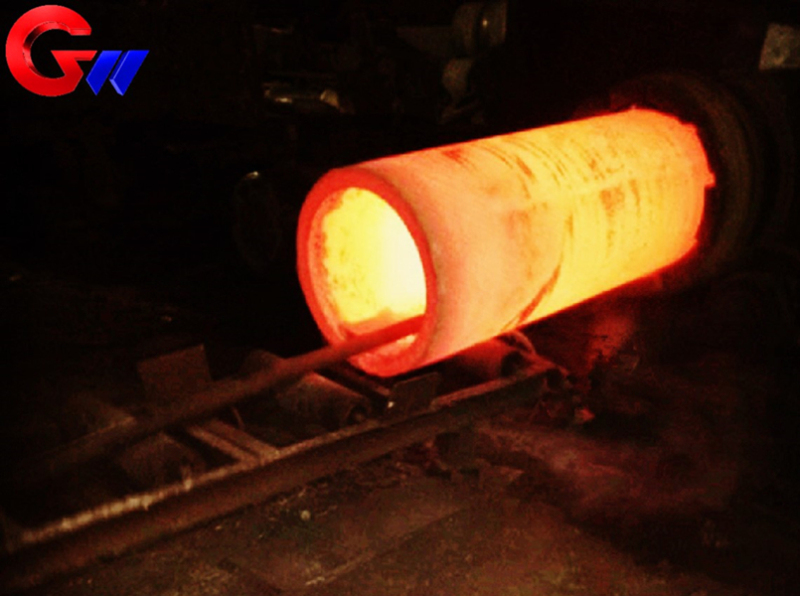

Centrifugal casting

Our company adopts advanced smelting and casting technology, with the equipment has accurate inspection to ensure the chemical composition of the casting steel reel material is reliable and accurate, also has the same characteristics. Centrifugal casting is adopted to guarantee the inner and outer surface of the casting steel reel is free from defects such as cracks, slag inclusion, pores and sand holes. Adopt mature heat treatment technology to ensure the mechanical properties of casting steel reel.

Description of heat treatment of steel sleeve

We will conduct heat treatment strictly for casting steel reel which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every steel reel product to achieve the best condition and customers’ good results.

Heat treatment process of casting steel reel (for cold rolling mill)

Purpose of process parameter requirements

Normalize 900 ± 10 ℃ for 2 hours, refine grain size by air cooling

Quenching 860 ± 10 ℃ oil quenching (cooling rate ≥ 80 ℃/s) to obtain martensite

Cryogenic -80 ℃ × 2h (optional) reduces residual austenite

Tempering at 550 ± 10 ℃ for 4 hours, water cooling quenching and tempering to 300~350HBW

Packing

We have excellent packaging team and mature packaging technology for our steel reel.

The packaging must ensure the safety of the products, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures product cleanliness. Confirm the cleanliness of product surface before packing.

Our steel reel products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Dynamic Balance Test Standard for 35CrMoV Cast Steel Sleeve (for Cold Rolling Mill)

Parameter requirement value detection equipment

Balance grade G2.5 (ISO 1940-1) hard supported dynamic balancing machine

Residual unbalance ≤ 1g · mm/kg (1500rpm) phase analyzer

Correction method for re drilling (depth ≤ 5mm) CNC drilling