Dedicated Stainless Steel Sleeve Of Aluminum Sheet And Strip Mill Machine

Steel spool is widely used in aluminum foil, aluminum plate, stainless steel foil belt and other industries of foil, plate, tape rolling.

Advantage of GW precision steel spool:

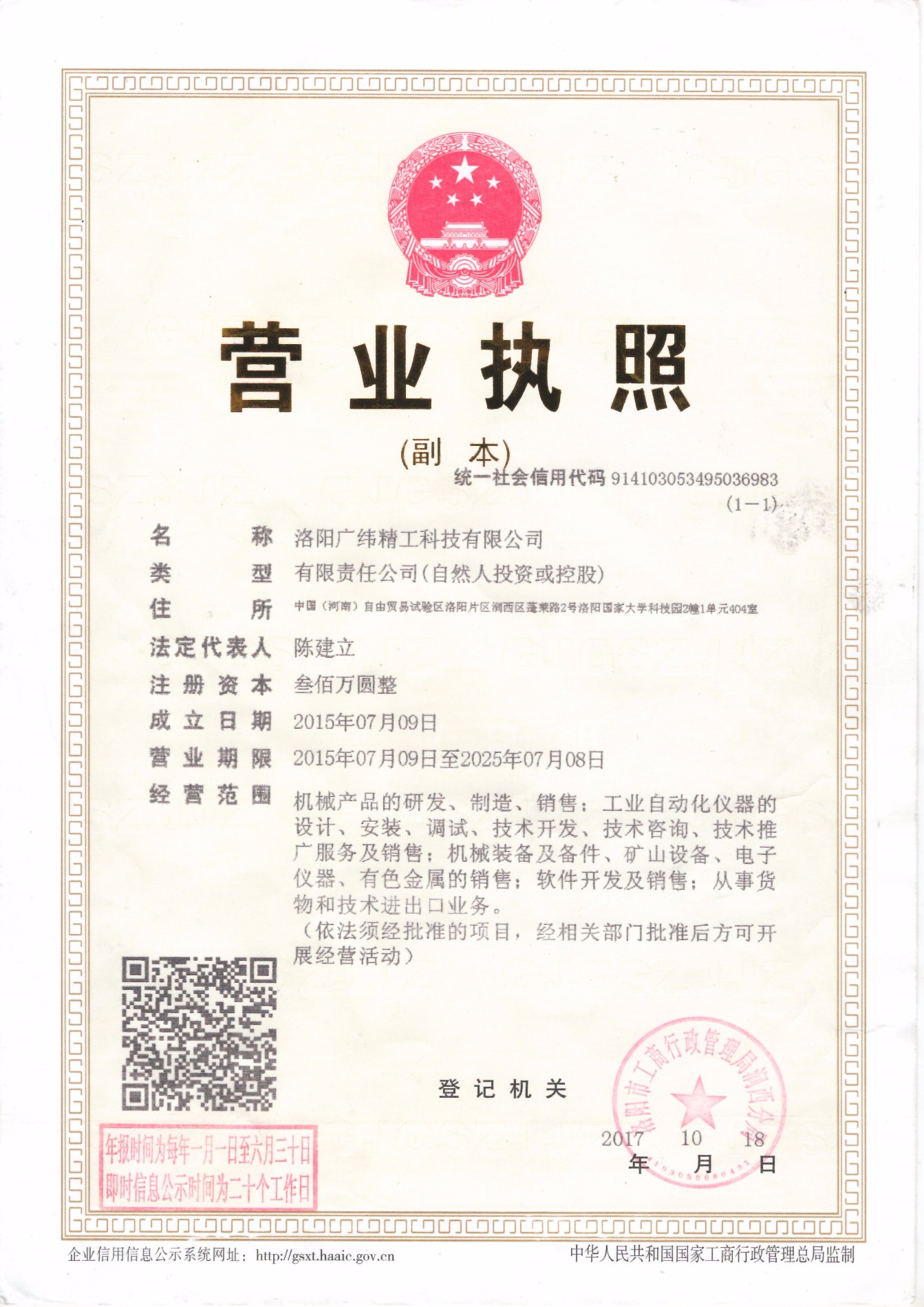

1、Our company has a well-developed management system. Meanwhile, our employees are highly qualified and skilled.

2、The company has a perfect management system of the guarantee of the after-sales service.

3、Our customers are already spread all over China, and our annual production capacity of the steel sleeve is 4000 sets per year.

- Guangwei Manufacturing Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Dedicated Stainless Steel Sleeve Of Aluminum Sheet And Strip Mill Machine

The specialized stainless steel sleeve for aluminum strip rolling mill is mainly used to support the rolling mill, transmit rolling force, and ensure the stability and shape accuracy of the rolling process. Its core characteristics are corrosion resistance, high stiffness, wear resistance, and it needs to adapt to the special working conditions of aluminum rolling (such as low rolling force and high surface quality requirements).

Application scenarios of stainless steel sleeves for aluminum plate and strip rolling mills

Core functions

Roll support: sleeved on the core shaft of the roll to prevent bending and deformation of the roll (especially suitable for support rolls of four roll/six roll mills)

Surface protection: isolate aluminum from direct contact with rollers to reduce scratches on the roller surface (aluminum is prone to sticking to rollers)

Force transmission: evenly distribute rolling pressure to improve the consistency of plate and strip thickness

Characteristics of working conditions

Temperature: 60-150 ℃ (cold rolling) or 200-300 ℃ (hot rolling aluminum billet)

Contact medium: rolling oil (containing ester additives), aluminum powder wear particles

Mechanical load: Radial pressure can reach 500-800MPa, requiring resistance to micro motion wear

| Steel Spool material | specification |

| 304 stainless steel | 355*305*1100 |

Mechanical properties of 304 stainless steel spool (annealed state, room temperature)

Typical value testing standards for performance indicators

Tensile strength (σ ₆) ≥ 515 MPa ASTM E8/E8M

Yield strength (σ ₀) ₂) ≥205 MPa

Elongation rate (δ) ≥ 40% (gauge length 50mm)

Hardness Rockwell hardness HRB 70-90 ASTM E18

Brinell hardness HB ≤ 201

Elastic modulus~193 GPa -

Additional explanation:

Cold processing effect: After cold rolling or cold drawing, the tensile strength of steel spool can be increased to 860-1200 MPa, but the elongation rate decreases to 12-25%.

High temperature performance: The upper temperature limit for short-term use is about 870 ° C (with good oxidation resistance), and it is recommended to use it ≤ 425 ° C for long-term use.

Low temperature toughness: Austenitic structure maintains good toughness at low temperatures and is suitable for environments below -200 ° C (such as liquid nitrogen storage).

Centrifugal Casting

Our company adopts advanced smelting and casting technology, with the equipment has accurate inspection to ensure the chemical composition of thesteel material is reliable and accurate, also has the same characteristics. Centrifugal casting steel is adopted to guarantee the inner and outer surface of the steel sleeve is free from defects such as cracks, slag inclusion, pores and sand holes. Adopt mature heat treatment technology to ensure the mechanical properties of steel spool.

Packing

We have excellent packaging team and mature packaging technology for steel sleeve.

The packaging must ensure the safety of the steel spool products, so that they will not be lost or damaged during transportation.

Packing ensures steel sleeves cleanliness. Confirm the cleanliness of dedicated stainless steel sleeve product surface before packing.

Our steel sleeve products are widely recognized and trusted by users and can meet continuously changing economic and social needs.