Customized Centrifugal Casting Steel Spool Of Cold Mill Machine

Advantages of Customized Centrifugal Casting Steel Spool Of Cold Mill Machine:

1. The company has our own professional processing of the design, develop and manufacture, also have proven machining technique.

2. Our company has a well-developed management system. Meanwhile, our employees are highly qualified and skilled.

3. The company has a perfect management system of the guarantee of the after-sales service.

4. Our customers are already spread all over China, and our annual production capacity of the Customized Centrifugal Casting Steel Spool Of Cold Mill Machine is 4000 sets per year.

5. Our company implements 6S management,(and) constantly improve the quality and skills of the staff, through the IE international quality system certification.

6. We also won the title of lixin unit research and development enterprise certificate, high-tech enterprise certificate and many other honors.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized Centrifugal Casting Steel Spool Of Cold Mill Machine

Product Application

Sleeve is widely used in aluminum,copper and stainless steel industry for foil, plate and sheet. GW precision has a strict requirement to concentricity of sleeve, dynamic balance and other requirements.

Product Informaiton

| sleeve material | specification |

| 35CrMoV | 665*605*2000 |

35CrMoV is a high-strength alloy steel with excellent comprehensive mechanical properties (high strength, high toughness, good hardenability), suitable for working conditions such as heavy load, high impact, and high temperature friction in cold rolling mills.

Application scenarios of centrifugal cast steel sleeve (customized) for 35CrMoV cold rolling mill

The main applications include:

Support roll/work roll journal protection sleeve

Used for four roll and six roll cold rolling mills to protect the roll neck, reduce wear, and extend the roll life.

Suitable for high-speed rolling (>1000m/min) and high rolling force (>5000kN) working conditions.

High precision rolling mill (such as HC rolling mill, UC rolling mill)

High dimensional stability is required to ensure the accuracy of roll positioning and reduce plate thickness fluctuations.

Resistant to high temperatures and corrosive environments

Suitable for scenarios where high temperature or corrosive media may occur, such as stainless steel, silicon steel, copper and aluminum rolling.

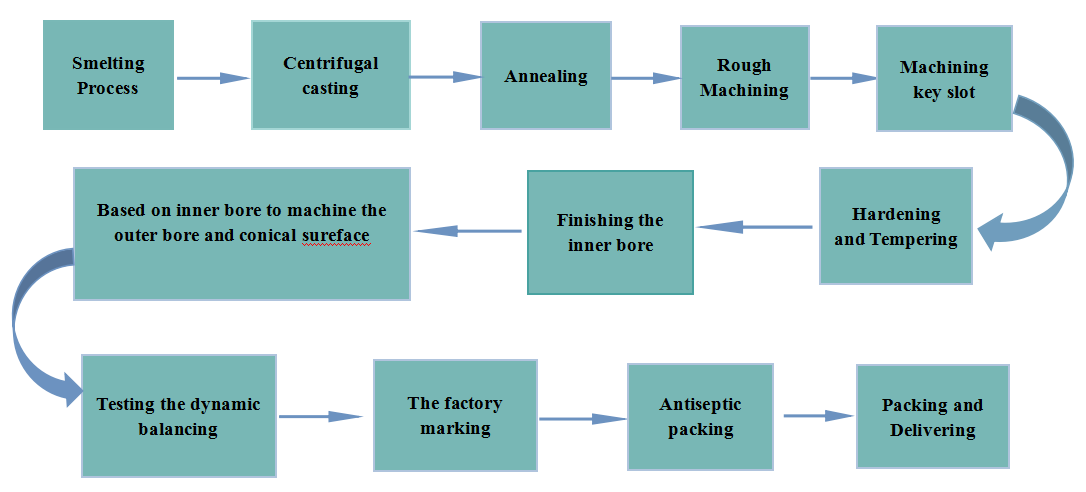

Production Process

Our company adopts advanced smelting and casting technology, centrifugal casting is adopted to guarantee the inner and outer surface of the sleeve is free from defects such as cracks, slag inclusion, pores and sand holes.

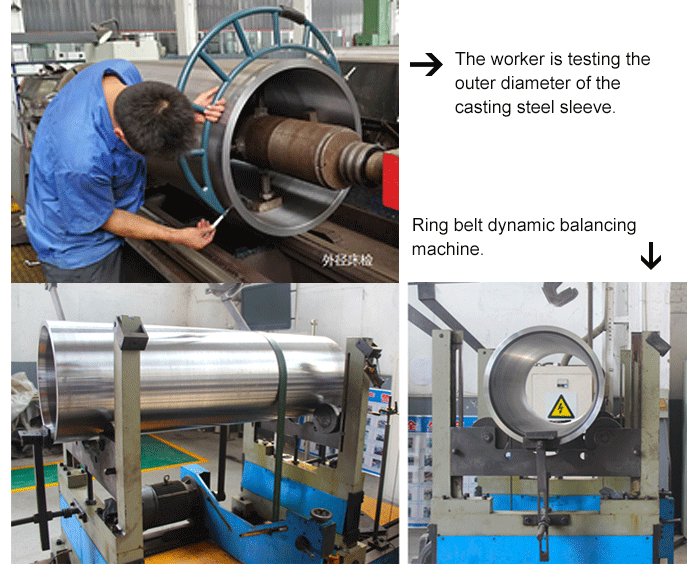

We used our independent dedicated device-hole drilling machine which is researched and developed by ourselves, it also obtain the national patent. Through continuous improvement, GW precision formed a integrated processing technic system to ensure concentricity, cylindricity, degree of symmetry and dynamic balance of the sleeve.

100% Dynamic Balancing Test for GW Steel sleeve

GW precision have conducted 100% dynamic balancing test for all our spools.

Product Packaging

We have excellent packaging team and mature packaging technology for our Customized Centrifugal Casting Steel Spool Of Cold Mill Machine.

Start your day off right by reaching out to GW Precision Technology Co.,Ltd. for any Customized Centrifugal Casting Steel Spool Of Cold Mill Machine spindle repair needs you may have.

Come see how we can save you downtime and keep you up and running.

guangwei@gwspool.com or +86-379-64593276