35CrMoV centrifugal cast steel sleeve for aluminum strip rolling mill

Application scenarios of 35CrMoV centrifugal cast steel sleeve for aluminum strip rolling mill

Applicable equipment

Four roll/six roll cold rolling mill: used for precision rolling of 1xxx-8xxx series aluminum alloy strip (thickness 0.3-6mm).

Hot rolling mill unit: suitable for hot rolling conditions of 400-600 ° C (requiring an external water cooling system).

Core functions

High precision transmission: Ensure that the radial runout of the rolling mill is ≤ 0.02mm (with a thickness tolerance of ± 0.5% for the strip).

Anti impact load: withstand the instantaneous impact force of biting steel (peak value up to 150% of rated load).

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

35CrMoV centrifugal cast steel sleeve for aluminum strip rolling mill

Material characteristics of 35CrMoV centrifugal cast steel sleeve for aluminum strip rolling mill

Chemical Composition (GB/T 3077 Optimization)

|Elements | C 0.32-0.38 | Cr 0.8-1.2 | Mo 0.2-0.4 | V 0.1-0.3 | Mn 0.5-0.8 | Si 0.2-0.4|

V microalloying: forming nano-sized VC precipitates, increasing fatigue strength by 25%.

Mechanical properties (after quenching and tempering treatment)

Typical value testing standards for indicators

Tensile strength 950-1100 MPa GB/T 228.1

Impact energy (-20 ℃) ≥ 45 J GB/T 229

Hardness HB 260-290 GB/T 231.1

Special Performance

Thermal expansion coefficient: 12.8 × 10 ⁻⁶/℃ (20-300 ℃), matched with aluminum alloy rolling temperature rise.

Wear resistance: sliding friction coefficient μ ≤ 0.15 (under lubrication conditions).

Product Information

| sleeve material | specification |

| 35CrMoV | 665*605*1600. |

Description of heat treatment of steel sleeve

We will conduct heat treatment strictly for steel sleeve which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every product to achieve the best condition and customers’ good results.

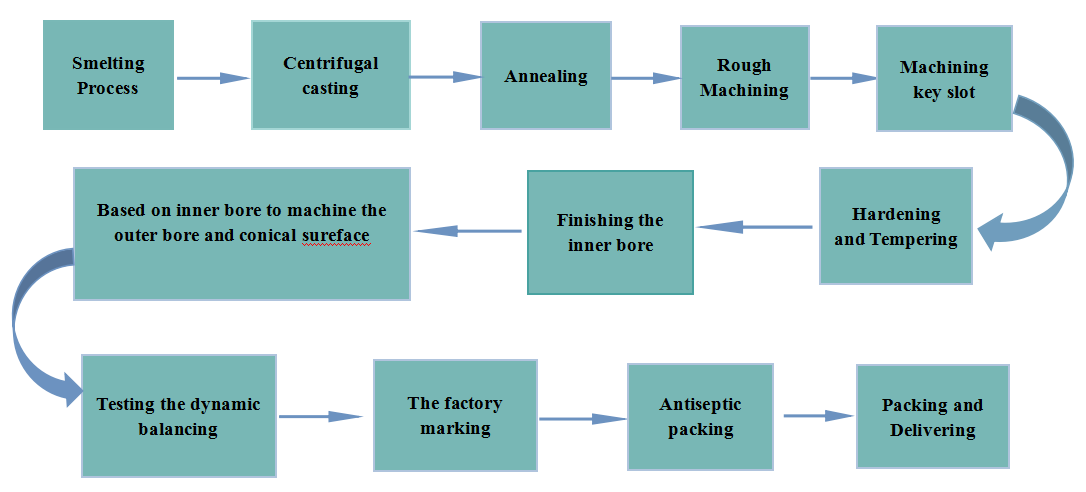

Manufacturing process of 35CrMoV centrifugal cast steel sleeve for aluminum strip rolling mill

Centrifugal Casting

Process parameters:

Speed: 800-1200rpm (adjusted according to the diameter of the sleeve)

Pouring temperature: 1580 ± 20 ℃

Cooling rate: 30-50 ℃/min (forced cooling by spraying water on the outer wall)

Organizational control: Obtain fine pearlite+ferrite matrix (grain size ≥ 6)

heat treatment

Double quenching and tempering:

880 ℃ × 2h oil quenching (cooling rate 80 ℃/s)

600 ℃ x 4h tempering (air-cooled)

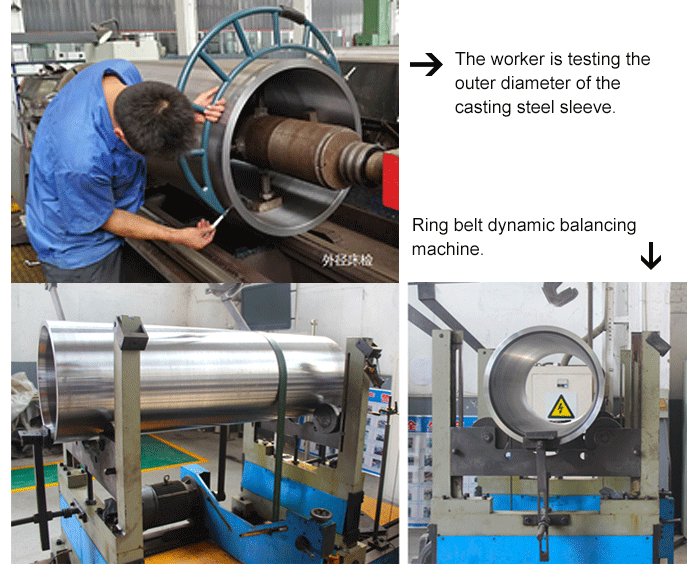

machining

Deep hole machining: BTA drilling (straightness ≤ 0.01mm/m) is used.

Surface treatment: Inner hole electrolytic polishing (Ra ≤ 0.4 μ m).

Dynamic Balancing Test

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

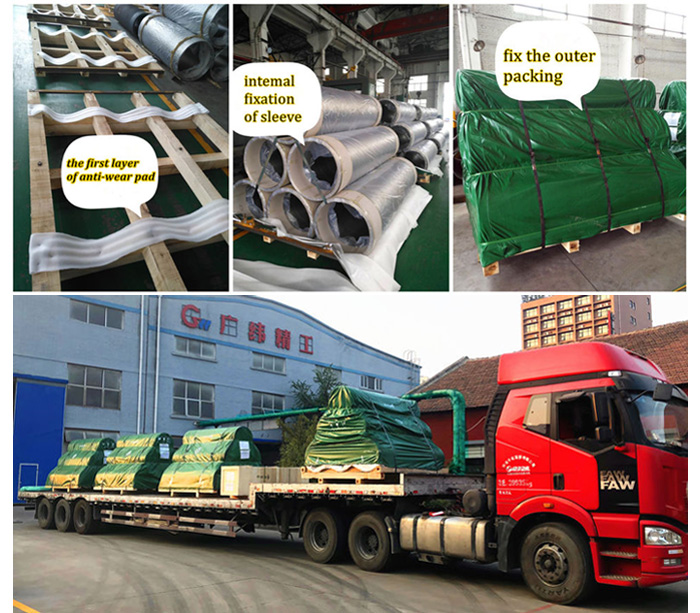

Product Packaging

We have excellent packaging team and mature packaging technology.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Packaging Specification for 35CrMoV Centrifugal Cast Steel Sleeve for Aluminum Strip Rolling Mill

Rustproof packaging

Inner layer: wrapped with vapor phase rust proof film (VCI)

Outer layer: 1.5mm thick waterproof kraft paper+PE wrapping film

Fixed transportation

Wooden tray (1200 × 1000mm), tied with steel straps (tension ≥ 500kgf)

Axial anti-collision foam pad (thickness ≥ 50mm)

Identification requirements

Laser engraving information:

Material grade: 35CrMoV

Heat treatment batch: QT-XXX

Maximum speed: 1500rpm (red label warning)