Customized centrifugal cast steel sleeve for aluminum foil rolling mill

Typical operating conditions for GW precision products:

High speed precision rolling: Suitable for aluminum foil mills with rolling speeds of 1000-2500m/min (6-30 μ m foil), with a dynamic unbalance requirement of ≤ 0.2g · cm/kg.

Thermal mechanical coupling load: The instantaneous temperature in the rolling zone is 150-300 ° C, and it needs to withstand alternating thermal stress (with more than 10 cycles).

Micro level vibration control: suppresses high-frequency vibration (amplitude ≤ 0.5 μ m) during rolling of thin foil.

Adapt to device types

Sengemir 20 roll rolling mill: Production of ultra-thin aluminum foil (battery foil/capacitor foil).

Four roll high-speed aluminum foil finishing mill: Rolling of finished double zero foil (≤ 6 μ m).

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized centrifugal cast steel sleeve for aluminum foil rolling mill

Product Information:

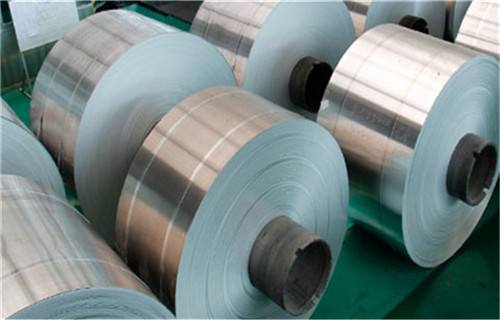

| Cast Steel Sleeve Material | Specification |

| CrMoV | 588*508*2000 |

Application scenarios of CrMoV centrifugal cast steel sleeve customized for aluminum foil rolling mill

CrMoV (such as 35CrMoV, 42CrMoV) centrifugal cast steel sleeves are designed for extreme working conditions of aluminum foil rolling mills due to their high strength, high temperature resistance, and fatigue resistance. They are mainly used for:

High speed precision rolling

Used for aluminum foil rolling mills (such as four roll and six roll mills), supporting the work roll/intermediate roll journal, suitable for rolling speeds of 1000~2000m/min.

Ensure that the thickness tolerance of ultra-thin aluminum foil (0.006-0.2mm) is ≤± 1%.

High temperature and heavy load environment

During rolling, the roller surface temperature should reach 150-250 ℃, and the sleeve should be resistant to thermal deformation.

Capable of withstanding rolling forces ranging from 3000 to 8000 kN and withstanding alternating impact loads.

Corrosion resistance requirements

Resist chemical corrosion of aluminum powder and rolling oil emulsion.

Key performance characteristics of customized centrifugal cast steel sleeve for aluminum foil rolling mill

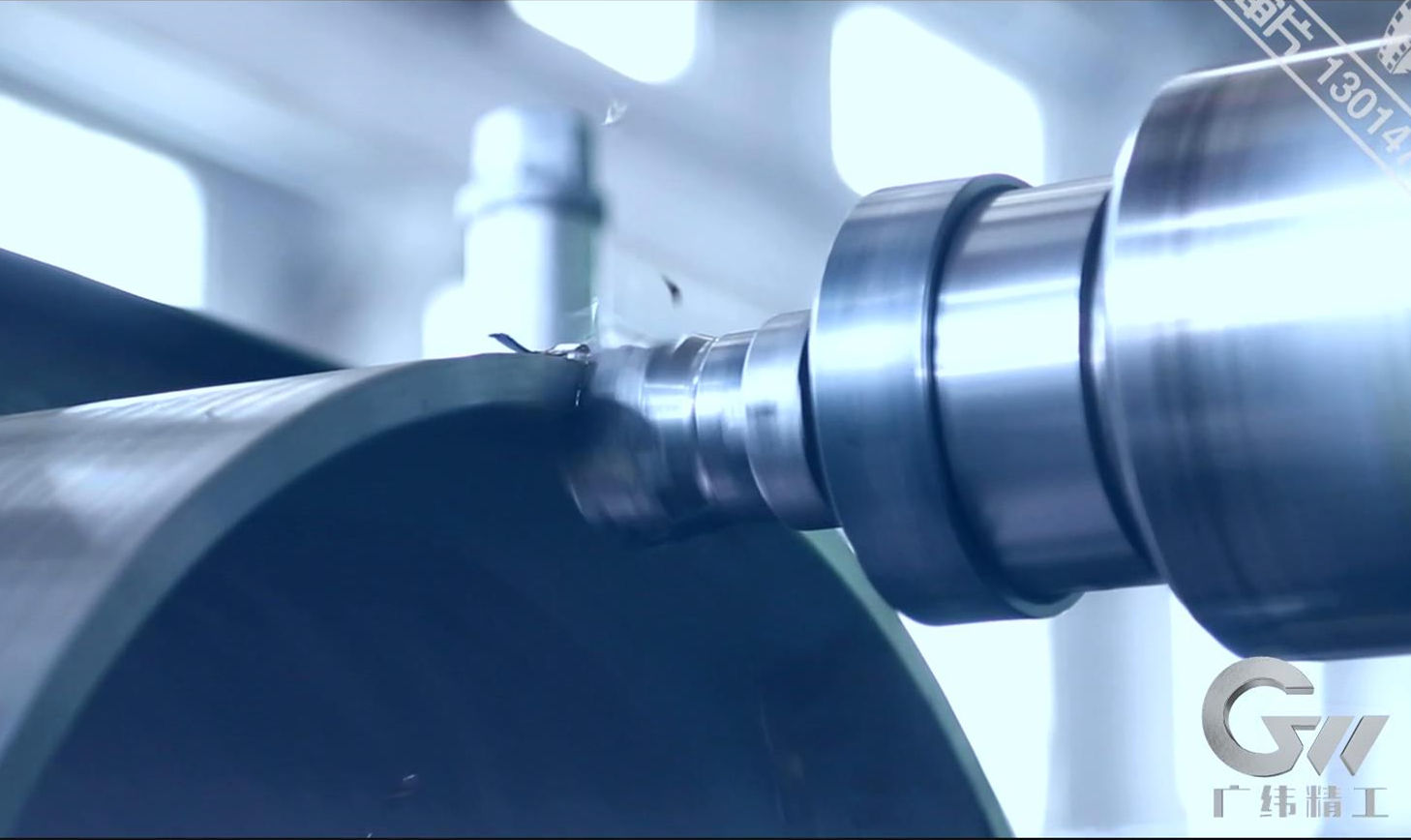

Materials and Manufacturing Processes

Material customization:

|Elements | C 0.25-0.35% | Cr 1.2-1.8% | Mo 0.3-0.6% | V 0.1-0.3% | Ni 0.5-1.0%|

Advantages of GW precision centrifugal casting sleeve:

Organizational density ≥ 98% (sand casting only 92%), defect rate<0.1%.

Outer wall hardness HB 260-300, inner hole HB 220-250 (gradient hardness design).

Heat treatment process:

Double quenching and tempering (880 ° C oil quenching+600 ° C tempering+secondary aging).

Inspection and testing:

Strict inspection and testing procedures are our quality assurance. Each centrifugal cast steel sleeve has a complete set of chemical composition analysis report, heat treatment report, material mechanical analysis report, dimensional tolerance, shape and position tolerance inspection report, all of which have traceability.

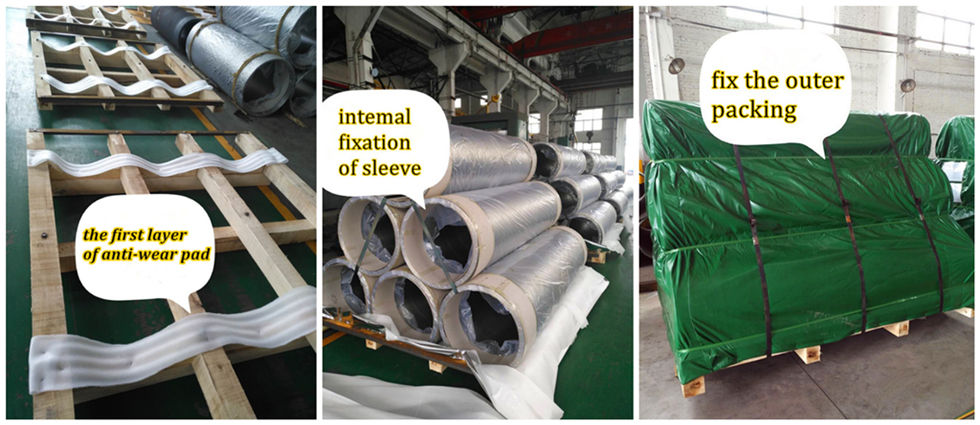

Packing

We have excellent packaging team and mature packaging technology for our centrifugal cast steel sleeve.

The packaging must ensure the safety of the products, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures product cleanliness. Confirm the cleanliness of product surface before packing.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Time is money,make the call now!

Related Products