Customized Casting Steel Spool Of Cold Rolling Mill Machine

The 35CrMoV cast steel sleeve customized for the cold rolling mill is a key component with high strength and wear resistance. Its production and manufacturing parameters require strict control of materials, heat treatment, processing accuracy, and mechanical properties to meet the high load, high precision, and long life requirements of the cold rolling mill.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized Casting Steel Spool Of Cold Rolling Mill Machine

Steel Sleeve Material | Specification |

35CrMoV | 665*605*2000 |

Material and Chemical Composition of Customized Cast Steel Sleeve for Cold Rolling Mill

1.1 Material Standards

Brand: 35CrMoV (GB/T 3077-2015)

Category: Low alloy high-strength cast steel (weldable, heat treatable)

Alternative materials: 34CrNiMo6 (DIN), AISI 4340 (American standard)

1.2 Chemical composition (%)

Element C Si Mn Cr Mo V P S

Range 0.30-0.38 0.20-0.40 0.50-0.80 0.90-1.20 0.20-0.30 0.10-0.20 ≤ 0.025 ≤ 0.025

Key features:

The Cr-Mo-V combination provides excellent hardenability, high temperature strength, and fatigue resistance.

Low S/P content reduces thermal brittleness and improves impact toughness.

Description of heat treatment of 35CrMoV cast steel sleeve

We will conduct heat treatment strictly for 35CrMoV cast steel sleeve which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every 35CrMoV cast steel sleeve product to achieve the best condition and customers’ good results.

Mechanical processing parameters of customized cast steel sleeves for cold rolling mills

4.1 Dimensions and tolerances

Parameter requirements

Inner hole diameter IT6 grade (H6), Ra ≤ 0.8 μ m

Outer diameter IT7 grade (h7), Ra ≤ 1.6 μ m

Cylindricity ≤ 0.01mm/100mm

Coaxiality ≤ 0.02mm (bearing mating surface)

4.2 Key Processing Techniques

Precision boring/honing: Ensure the accuracy of the inner hole (such as for bearing fitting).

Grinding: Processing with an external cylindrical grinder to avoid thermal deformation.

Dynamic balance (if rotating at high speed): residual unbalance ≤ G2.5 level (ISO 1940).

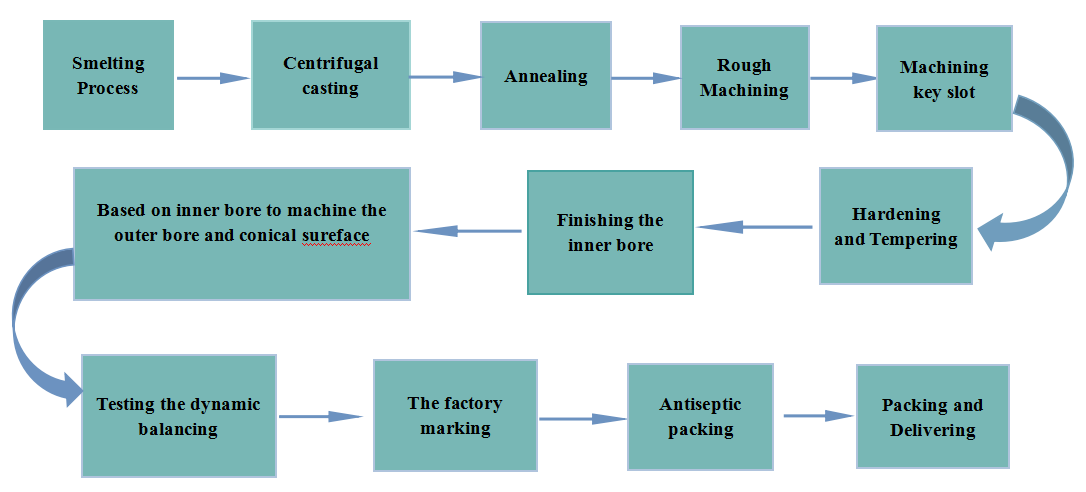

We used our independent dedicated device-hole drilling machine which is researched and developed by ourselves, it also obtain the national patent. The machine is provided with good rigid, no returning clamp and machine and high accuracy on the processing of machining. Through continuous improvement, our company formed a integrated processing technic system to ensure concentricity, cylindricity, degree of symmetry and dynamic balance of the 35CrMoV cast steel sleeve. Specific accuracy tolerance and geometric accuracy tolerance is strictly according to the customers’ requires.

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of 35CrMoV cast steel sleeve products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

Packing

We have excellent packaging team and mature packaging technology for each 35CrMoV cast steel sleeve.

The packaging must ensure the safety of the products, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures product cleanliness. Confirm the cleanliness of product surface before packing.

Our steel sleeve products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Start your day off right by reaching out to GW Precision Technology Co.,Ltd. for any steel sleeve spindle repair needs you may have.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!

guangwei@gwspool.com or +86-379-64593276

FAQ

1. Can You Make This Product According To The Customer's Requirement?

A: Yes, we can follow your specific requirements.

2. Can I Visit Your Factory Before We Ordering ?

A: Yes, welcome to our factory for field trip.

3. Where Is The Nearest Port To You Company?

A: Shanghai port is the nearest one.

4. Can We Choose Different Materials?

A: Yes, it can be selected depend on your requirements.

5. How Long Gone Take When You Finsh The Product And Deliver To Me?

A: It usually takes one and a half to two months by sea. It depends on the quantity of your order.

6. What Is Your Cover Of The Package?

A: We use wooden box to export.