Customized 35CrNiMo Steel Sleeve Of Cold Mill Machine

GW precision has its own professional processing design, development, and manufacturing, as well as mature processing technology for 35CrNiMo steel sleeve.

GW precision has a comprehensive management system. At the same time, our employees have high quality and superb skills.

- Guangwei Manufacturing Precision

- Henan,Luoyang

- Contractual Stipulation

- Information

Customized 35CrNiMo Steel Sleeve Of Cold Mill Machine

Customized 35CrNiMo Steel Sleeve Of Cold Mill Machine

sleeve material | specification |

35CrNiMo | 665*605*2000 |

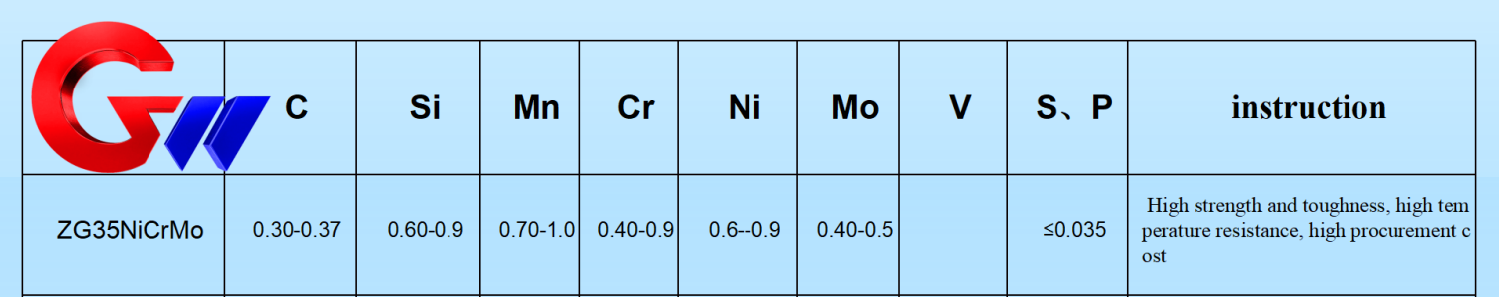

Chemical composition of 35CrNiMo (mass percentage) Steel sleeve

Execution standards: GB/T 3077-2015 (China), ASTM A434 (American standard)

Range of Element Content (%) Function

Carbon (C) 0.32-0.40 ensures strength and hardness, forming a carbide strengthening phase

Chromium (Cr) 0.60-0.90 improves hardenability, corrosion resistance, and high-temperature strength

Nickel (Ni) 1.40-1.80 significantly improves low-temperature toughness and stabilizes austenite structure

Molybdenum (Mo) 0.15-0.25 suppresses temper brittleness and enhances creep resistance

Manganese (Mn) 0.50-0.80 assists in hardenability and improves thermal processing performance

Silicon (Si) 0.17-0.37 deoxidation to improve strength

Phosphorus (P) ≤ 0.025 impurities (strictly controlled)

Sulfur (S) ≤ 0.025 impurities (affecting thermal brittleness)

Production and Manufacturing Process of 35CrNiMo Customized Steel Sleeve for Cold Rolling Mill

1. Special forging

Radial and axial ring forging (radial and axial rolling ratio ≥ 6:1)

Temperature control cooling: spray cooling rate 15 ℃/s (to avoid bainite transformation)

2. Precision machining

Internal hole processing:

Deep hole boring (straightness 0.005mm/m) → honing (Ra 0.05 μ m)

Outer circle processing:

CNC turning (with a grinding allowance of 0.1mm) → thread grinding machine (lead error ≤ 3 μ m/100mm)

3. Heat treatment process

A [850 ℃ × 2h oil quenching] -->B [-73 ℃ × 24h cryogenic treatment]

B -->C [580 ℃ × 4h secondary tempering]

C -->D [200 ℃ × 12h aging stabilization]

Note: Residual austenite<1%, hardness HRC38-42

4. Surface integrity control

Shot peening strengthening (coverage rate 200%, Almen strength 0.35-0.4mmA)

Electrolytic polishing (removing surface microcracks, increasing fatigue life by 40%)

Since the very beginning of 35CrNiMo steel sleeve production, the GW precision formed the principle of top-ranking products, quality and service.

We serve our customers with strict quality inspection and technology control of 35CrNiMo steel sleeve.

The 35CrNiMo steel sleeve products are popular among domestic aluminium processing plants and some abroad companies in Europe and India.

Basing on the experiments of decade years, we had designed the horizontal automatic boring machine independently and received the state certification of invention for 35CrNiMo steel sleeve.

By doing so, we manage to enhance the quality of processing the inner hole, releasing the labor tension and improving the efficiency.

During the process of outer hole, we use the advanced CNC automatic machine tool to replace the old one. This allows company to improve the quality and efficiency, releasing the labor tension of the 35CrNiMo steel sleeve.