Customized 35CrNiMo Steel Reel Of Copper Plate

Copper strip manufacturers use unwinders in their production process, which are usually equipped with GW precision steel sleeves. GW precision steel sleeves are mainly being used to help unroll the coils and ensure that the production line can run continuously.

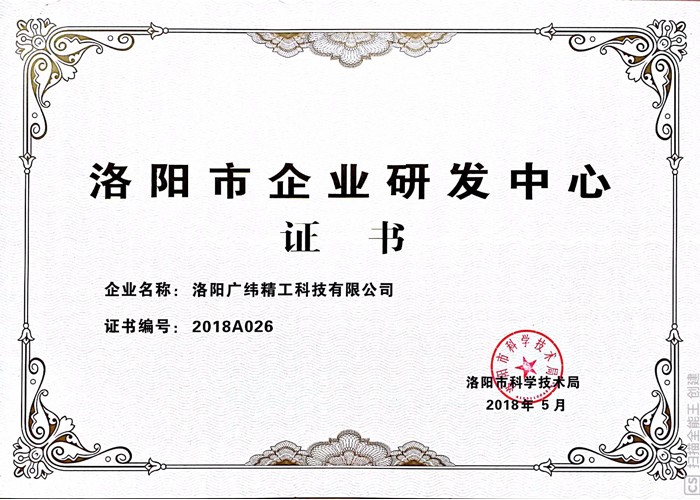

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized 35CrNiMo Steel Reel Of Copper Plate

35CrNiMo steel sleeve for copper strip production is a customized component with high strength and wear resistance, mainly used for roll neck protection of support rolls or intermediate rolls in copper strip rolling mills.

Application scenarios of 35CrNiMo steel sleeve (customized) for copper strip

Copper strip rolling production line

Used to support the neck of the roller/intermediate roller to prevent wear or deformation caused by rolling force.

Endure high cycle alternating loads (repeated rolling forces) and slight impacts (such as the moment of plate and strip biting).

Characteristics of working conditions

Temperature: 80~150 ℃ (rolling friction heat+copper strip conduction heat).

Corrosion environment: Contact with emulsion or rolling oil requires certain corrosion resistance.

Matching accuracy: interference fit with the roll neck (interference amount 0.05~0.10mm), requiring high dimensional stability.

Material selection for 35CrNiMo steel sleeve (customized) for copper strip: 35CrNiMo steel

Composition characteristics (typical values):

C: 0.32~0.40%, Cr: 0.60~0.90%, Ni: 1.25~1.65%, Mo: 0.15~0.25%。

Advantages:

Ultra high strength (tensile strength ≥ 980MPa) and toughness (impact energy ≥ 50J).

Excellent hardenability (suitable for heat treatment of large section parts).

Good fatigue resistance and suitable for alternating load conditions.

Key Quality Control Points for 35CrNiMo Steel Sleeve (Customized) for Copper Strip

Material purity: Control the P and S content (≤ 0.015%) to avoid temper brittleness.

Uniformity of heat treatment: Large section parts require segmented heating or rotary quenching.

Residual stress relief: Add vibration aging treatment before precision machining.

Copper strip manufacturers use unwinders in their production process, which are usually equipped with GW precision steel sleeves. GW precision steel sleeves are mainly being used to help unroll the coils and ensure that the production line can run continuously. Below are some more details about uncoilers and their sleeves:

GW precision sleeve specification isΦ570*Φ500*1830.

The uncoiler is an important piece of equipment in a continuous strip line, and its main function is to unroll the coils to provide the line with a continuously running strip. This is essential to keep the line running efficiently.

The customized 35CrNiMo steel reel of copper plate is one of the key components of the uncoiler, and it is mainly used to support and unroll the steel coil. The use of GW precision steel sleeve prevents damage to the reel coil during unrolling, thus improving the quality of the strip. In addition, the steel sleeve can help to realize the quick change of different coil inner diameters, which saves time and cost for the enterprise.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We also have excellent packaging team and mature packaging technology.

Related Products

Steel Sleeve

Customized Steel Sleeve

Customized 35CrNiMo Steel Reel Of Copper Plate