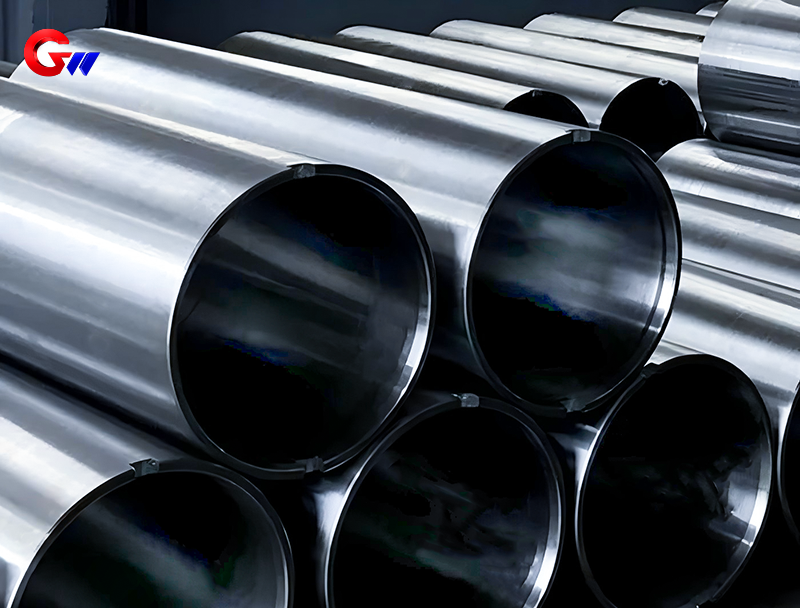

35CrNiMo steel sleeve for aluminum strip rolling mill

Advantages of GW precision spool:

1. The company has our own professional processing of the design, develop and manufacture, also have proven machining technique.

2. Our company has a well-developed management system. Meanwhile, our employees are highly qualified and skilled.

3. The company has a perfect management system of the guarantee of the after-sales service.

4. Our customers are already spread all over China, and our annual production capacity of the sleeve is 4000 sets per year.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized 35CrNiMo Steel Reel Of Aluminum Sheet And Strip Mill Machine

Product Application

35CrNiMo steel sleeve for aluminum strip rolling mill is widely used in aluminum foil, plate, stainless steel foil belt and other industries of foil, plate, tape rolling. Therefore, GW precision has a strict requirement to concentricity of steel sleeve.

Product Information

| sleeve material | specification |

| 35CrNiMo | φ565*φ505*1600 |

35CrNiMo is a high-strength alloy structural steel with excellent strength, toughness, fatigue resistance, and hardenability, particularly suitable for high-precision and high-speed rolling conditions of aluminum foil mills.Material characteristics of customized 35CrNiMo steel sleeve for aluminum foil rolling mill (35CrNiMo)

Advantages of Performance Index Parameter Range

Tensile strength (Rm) ≥ 980 MPa, high bearing capacity, deformation resistance

Yield strength (Rp0.2) ≥ 835 MPa, impact resistance, fatigue resistance

Good plasticity with elongation (A5) ≥ 12% to prevent brittle cracking

Impact toughness (AKV) ≥ 63 J (room temperature), resistant to alternating loads, suitable for frequent start stop

Hardness (after quenching and tempering) HRC 32-38 (can be surface quenched to HRC 45+), high wear resistance, and extended service life

Chemical composition (typical value, wt%):

C: 0.32~0.40 | Si: 0.17~0.37 | Mn: 0.50~0.80

Cr: 0.80~1.10 | Ni: 1.30~1.70 | Mo: 0.15~0.25

Production and manufacturing process of customized 35CrNiMo steel sleeve for aluminum foil rolling mill

1. Preparation of forged blanks (superior to casting)

Heating of steel ingots: homogenization treatment at 1200-1250 ℃.

Forging/Free Forging: Slow cooling after forming to avoid white spot defects.

2. Heat treatment (core process)

Normalization (880 ℃ × 2h, air cooling): Refine grain size and eliminate forging stress.

Quenching and tempering treatment:

Quenching: 850 ℃ × 2h oil quenching to obtain martensitic structure.

Tempering: 550~600 ℃ for 4 hours, tempering with martensite to balance strength and toughness.

Surface strengthening (optional):

High frequency quenching: surface hardness HRC 45~50, depth 2-3mm.

Our company adopts advanced smelting and casting technology, centrifugal casting steel material will ensure

the chemical composition be reliable and accurate.

Description of heat treatment of steel sleeve

GW precision will conduct heat treatment strictly for 35CrNiMo steel sleeve which have the specific demand in mechanical property.

To assure better quality of 35CrNiMo steel sleeve products, GW precision have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.