Customized 35CrMoV Steel Spool Of Cold Rolling Mill Machine

35CrMoV is a high-strength and high toughness alloy structural steel, which has excellent comprehensive mechanical properties after quenching and tempering heat treatment. It is widely used in high load and high-precision components of cold rolling mills for steel spool.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized 35CrMoV Steel Spool Of Cold Rolling Mill Machine

sleeve material | specification |

35CrMoV | 665*605*2000 |

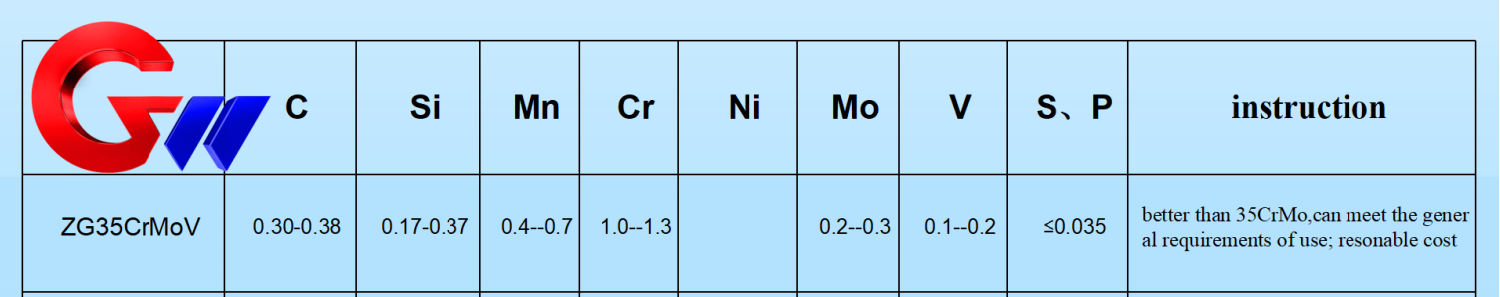

Production and manufacturing parameters of customized 35CrMoV steel sleeve for cold rolling mill

GW precision 35CrMoV steel sleeve Key features:

The Cr-Mo-V combination provides high hardenability, fatigue resistance, and high-temperature strength.

Low S/P content reduces thermal brittleness and improves impact toughness.

Mechanical properties of 35CrMoV (quenched and tempered: quenching+high-temperature tempering)

Typical value testing standards for performance indicators

Tensile strength (σ ₆) 900-1100 MPa GB/T 228.1 (ISO 6892)

Yield strength (σ ₀) ₂) 750–950 MPa

Elongation rate (δ) ≥ 12% with a gauge length of 5d (where d is the diameter of the specimen)

Impact energy (AKU) ≥ 50 J (at room temperature) GB/T 229 (ISO 148)

Hardness HRC 28-35 (quenched and tempered state) GB/T 230.1

Sectional shrinkage rate (ψ) ≥ 45%

Key feature supplement:

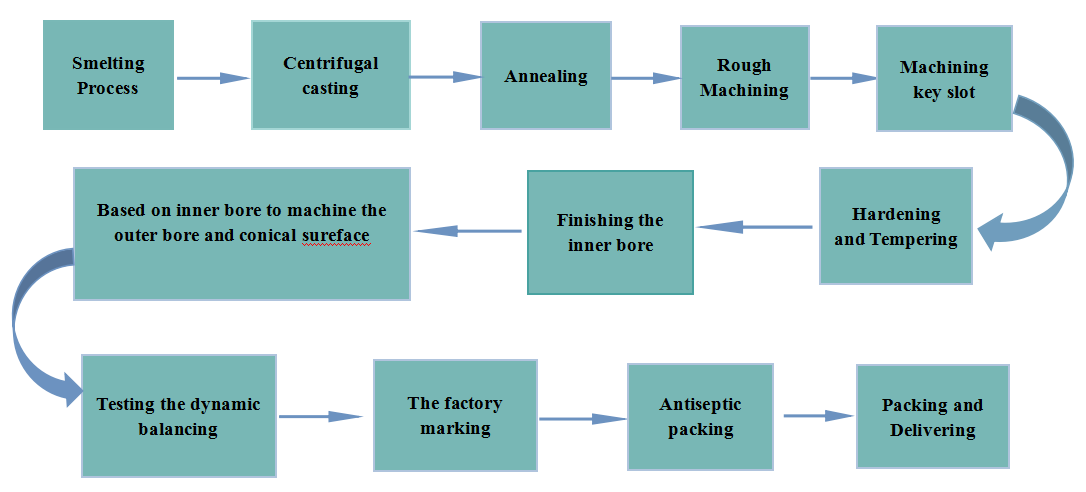

Heat treatment process:

Quenching: Oil cooled at 850-880 °C to obtain martensitic structure.

Tempering: 550-650 ° C, adjust temperature according to strength requirements (temperature ↑ → strength ↓, toughness ↑).

High temperature performance:

Maintain stable strength below 400 ° C and can withstand 500 ° C in the short term (molybdenum enhances creep resistance).

Fatigue limit:

Approximately 450-500 MPa (10 cycles, smooth specimen), suitable for dynamic load components.

Mechanical processing parameters of customized 35CrMoV steel sleeve for cold rolling mill

Parameter requirements

Inner hole diameter IT6 grade (H6), Ra ≤ 0.8 μ m

Outer diameter IT7 grade (h7), Ra ≤ 1.6 μ m

Cylindricity ≤ 0.01mm/100mm

Coaxiality ≤ 0.02mm (bearing mating surface)

Key processing techniques:

Precision boring/honing: Ensure the accuracy of the inner hole.

Grinding: Processing with an external cylindrical grinder to avoid thermal deformation.

Dynamic balance (high-speed rotation): residual unbalance ≤ G2.5 level (ISO 1940).

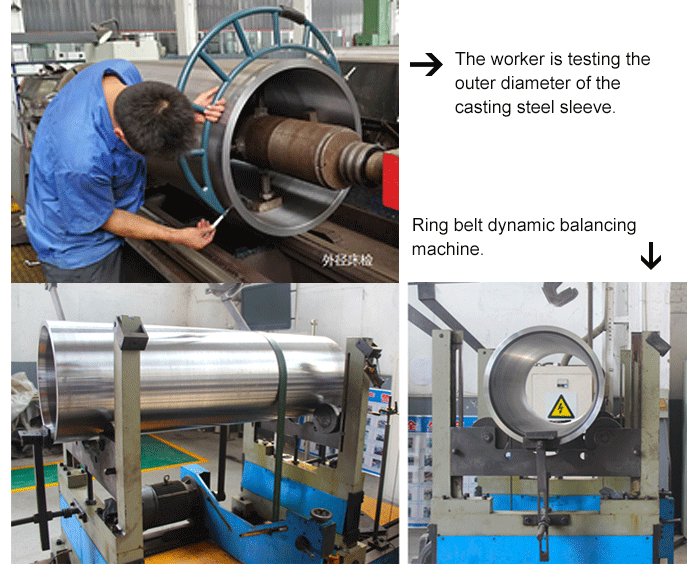

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of 35CrMoV steel sleeve products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

Packaging

We have excellent packaging team and mature packaging technology.

The packaging must ensure the safety of the products, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures product cleanliness. Confirm the cleanliness of product surface before packing.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Key considerations for customized cast steel sleeves for cold rolling mills

Welding repair: 35CrMoV welding requires preheating (200-300 ℃) and stress relief annealing after welding.