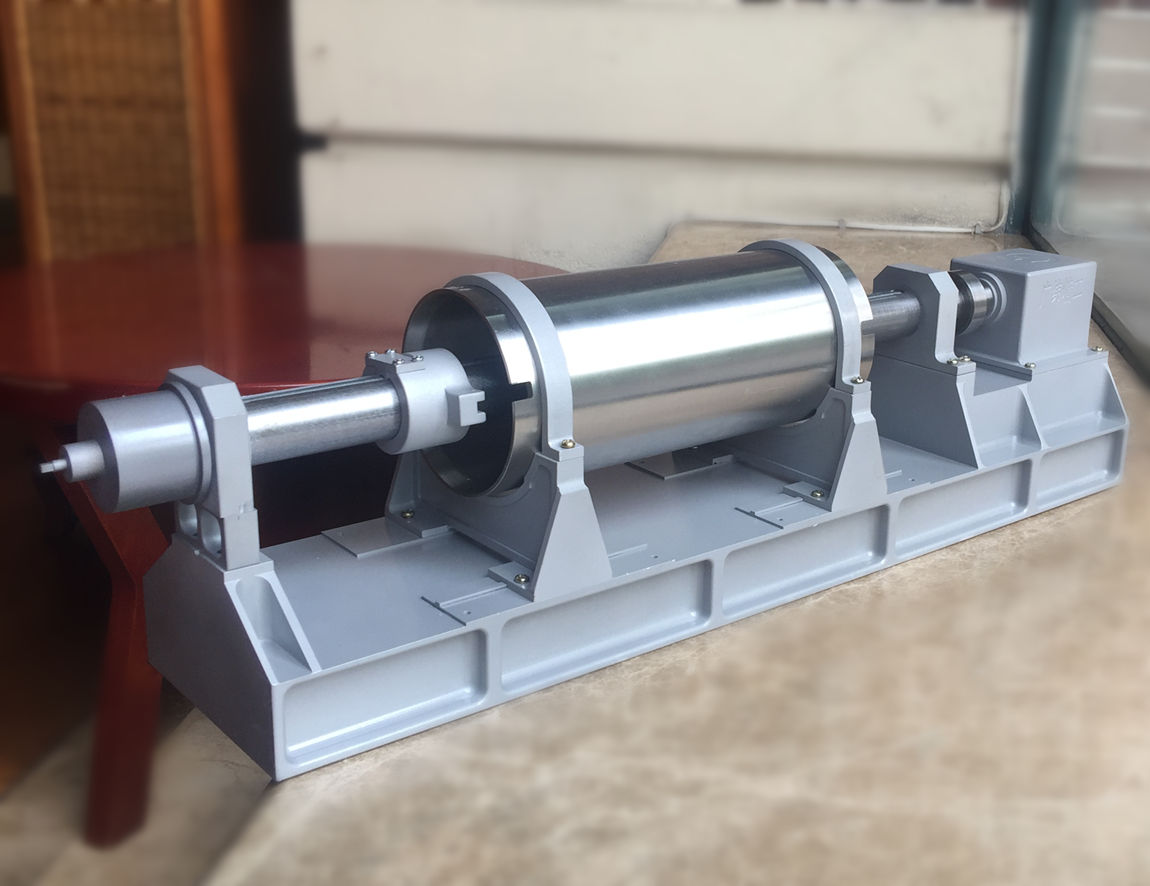

Customized 35CrMoV Steel Sleeve Of Stand Mill

The customized steel sleeve material is 35CrMoV, and one of the 35CrMoV sleeve specification is 665*605*2000.

GW Precision provide at least 4000pcs customized steel sleeves to domestic and abroad customers every year.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized 35CrMoV Steel Sleeve Of Stand Mill

35CrMoV steel is a medium carbon alloy structural steel with high strength, good toughness, and wear resistance, commonly used in the manufacture of components that can withstand heavy loads, impacts, and fatigue.

Application scenario of customized 35CrMoV steel sleeve for vertical rolling mill

35CrMoV steel sleeve is mainly used in the following scenarios in vertical rolling mills:

Roll support and positioning: As a supporting component of the rolling mill, it bears the radial and axial forces during the rolling process.

Wear resistance and impact resistance: resist the friction and impact of rolled materials under high-speed rolling or heavy load conditions.

High temperature environment: During the hot rolling process of some rolling mills, the sleeve needs to withstand a certain temperature (which needs to be coordinated with the heat treatment process).

Heat treatment process for customized 35CrMoV steel sleeve for vertical rolling mill

The heat treatment of 35CrMoV steel is crucial and directly affects the strength, toughness, and service life of the sleeve

Quenching and tempering treatment (quenching+high temperature tempering)

Quenching: Heat to 850-880 ℃ (austenitization), hold for heat and then oil or water quench to obtain martensitic structure.

Tempering: Temper at 540-600 ℃ for 2-4 hours to relieve stress and obtain tempered martensite, balancing strength and toughness.

Goal: Tensile strength ≥ 980 MPa, impact toughness ≥ 50 J/cm ².

Surface strengthening (optional)

High frequency quenching: Local quenching of the contact surface to increase surface hardness (HRC 50~55).

Nitriding treatment: Gas nitriding is carried out at around 500 ℃ to increase surface wear resistance and fatigue resistance.

The customized steel sleeve material is 35CrMoV, and one of the 35CrMoV sleeve specification is 665*605*2000.

The blank of 35CrMoV sleeves will be processed on the hole drilling machine, which was developed and manufactured by GW Precision with patent.

With help of the boring machine, the customized steel sleeve blank can be adjusted to concentric of both the front and rear ends of the aperture,as to achieve smooth cutting and improve machining accuracy.

In the cutting process, the 35CrMoV sleeve is fixed without rotating, and the way that tool shaft rotates to cut the inner hole avoid the error of taper or other shapes.

Inspection and testing:

Strict inspection and testing procedures ensure our quality. Each 35CrMoV sleeve has strictly inspection and provide a complete set of reports on chemical composition analysis, heat treatment, mechanical properties and dimensional tolerance.