Customized 35CrMoV Steel Sleeve Of Aluminum Foil Mill Machine

35CrMoV Steel Sleeve is the preferred solution for ultra-thin rolling of aluminum foil, and GW precision 35CrMoV Steel Sleeve performance advantages are particularly prominent in the production of aluminum foil below 6 μ m. However, strict control of heat treatment and surface treatment processes is required to unleash its potential.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized 35CrMoV Steel Sleeve Of Aluminum Foil Mill Machine

Sleeve material | Specification |

35CrMoV | 465*405*1050 |

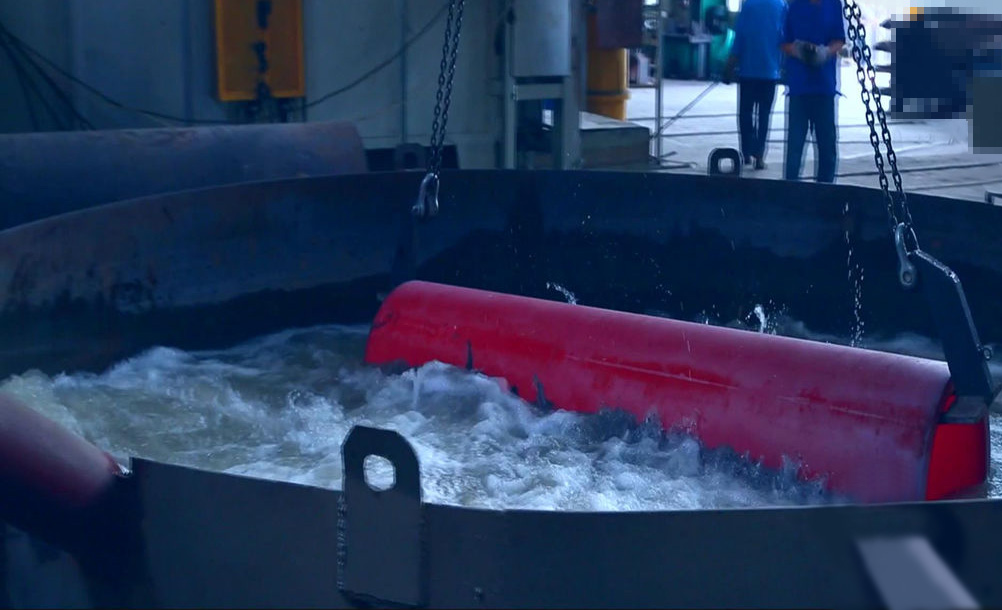

Centrifugal casting

Application of 35CrMoV steel sleeve (customized) for aluminum foil rolling mill

Aluminum foil rolling mill roll support

As the core component of precision rolling mill, it can withstand micro level dynamic loads during ultra-high speed (up to 2000rpm) and extremely thin aluminum foil (≤ 0.006mm) rolling, ensuring that the radial runout of the rolling mill is ≤ 0.005mm.

Adaptation to high temperature working conditions

Suitable for local temperature rise caused by deformation heat during the rolling process (up to 300 ℃ in the short term), to avoid thermal deformation affecting the control of aluminum foil thickness difference.

Performance characteristics of 35CrMoV steel sleeve (customized) for aluminum foil rolling mill

Balance between ultra-high strength and toughness

After quenching and tempering treatment, the tensile strength of 35CrMoV is ≥ 1000MPa, the yield strength is ≥ 850MPa, and it maintains an impact energy of ≥ 50J (-20 ℃), which is suitable for the impact load of aluminum foil rolling mill.

Excellent fatigue life

The V element refines the grain size, increasing the fatigue limit by 15-20% compared to 35CrMo, and the theoretical cycle life is greater than 10 times (load amplitude of 300MPa).

Precision wear resistance

Surface nitriding (hardness ≥ HV900, layer depth 0.2-0.3mm) or laser quenching (hardness HRC50-55) reduces the friction coefficient with the rolling mill (μ<0.1).

high temperature stability

The hardness retention rate of Mo-V composite carbide at 300 ℃ is greater than 90%, which is better than that of ordinary alloy steel.

dimensional stability

The residual stress after heat treatment is less than 50MPa, and the radial thermal expansion coefficient during high-speed operation is ≤ 1.2 × 10 ⁻⁶/℃.

Advantages of customized 35CrMoV steel sleeve for aluminum foil rolling mill

High precision rolling guarantee: Material rigidity (elastic modulus of 210GPa) and damping characteristics suppress vibration, and the thickness difference of aluminum foil can be controlled within ± 0.5 μ m.

Anti micro motion wear: Especially suitable for micro amplitude relative sliding conditions between the rolling mill and the sleeve.

Customization potential: Different rolling mill load spectra can be matched through component fine-tuning (such as V content 0.1-0.3%)

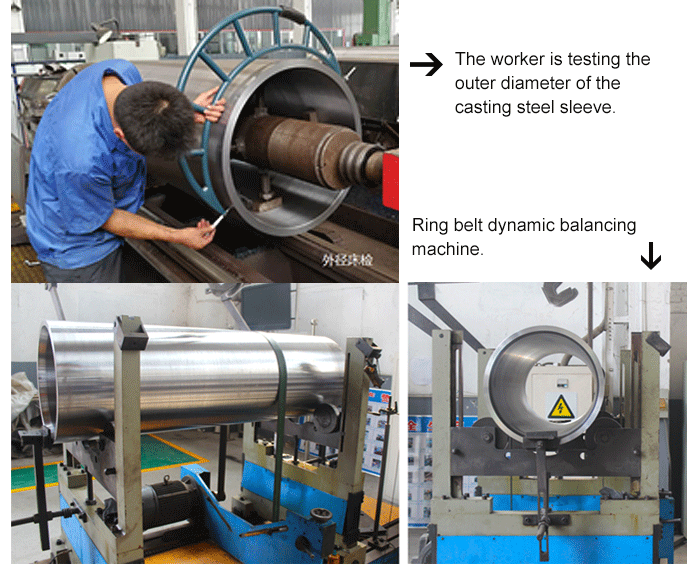

Dynamic balancing test

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of 35CrMoV steel sleeve products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

Packing and Delivery

We have excellent packaging team and mature packaging technology.

Our 35CrMoV steel sleeve are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Start your day off right by reaching out to Luoyang Guangwei Precision Manufacturing Technology Ltd. for any 35CrMoV steel sleeve spindle repair needs you may have.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

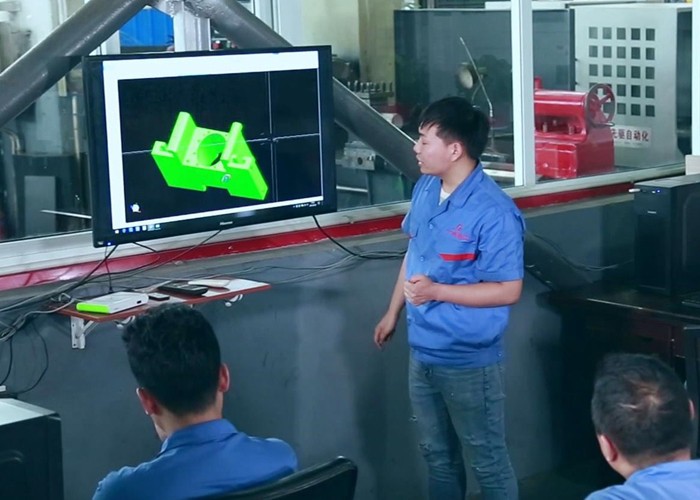

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!

guangwei@gwspool.com or +86-379-64593276