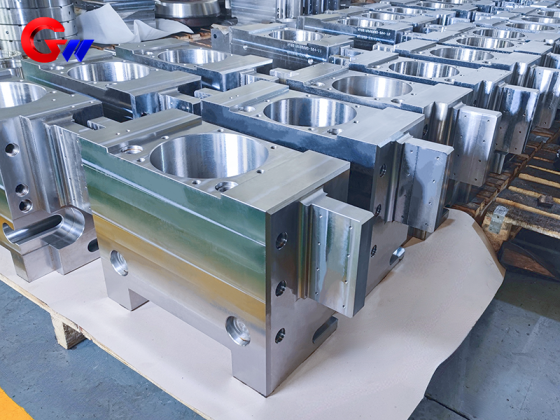

Cold Rolling Mill Machine Of The Transimit Side Intermediate Roller Bearing Block

GW precision accept other non-standard bearing chocks customizing from customers.

Cold Rolling Mill Machine Bearing Chock Material:

working roll (forgings):45 steel,40Cr,42CrMo

support roll (castings): zg310-570, zg270-500.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity is 1000 pieces

- Information

Cold Rolling Mill Machine Of The Transimit Side Intermediate Roller Bearing Block

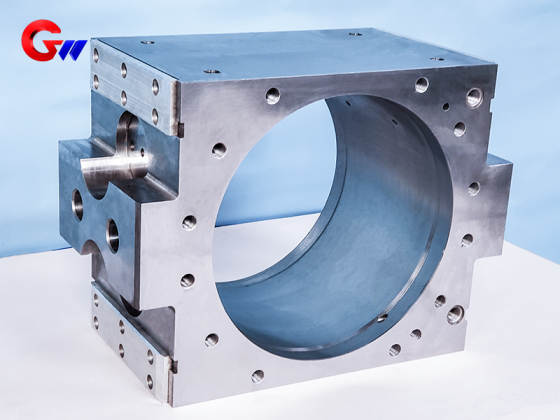

The bearing seat of the intermediate roll on the transmission side of the cold rolling mill is an important component in the cold rolling mill, mainly used to support and position the intermediate roll, ensuring the uniform transmission of rolling force and the stability of the roll system

Application scenario of intermediate roller bearing seat on the transmission side of copper in cold rolling mill

function

Support the intermediate roll to withstand the radial and axial forces transmitted during the rolling process (especially the intermediate roll in a six roll rolling mill).

Adjust the axial position of the intermediate roller through the bearing seat (such as the lateral movement function in HC rolling mill) to control the plate shape.

Need to adapt to high-frequency vibration, heavy load impact, and rolling oil/coolant corrosion environment.

Typical applications

Six roll mill (UC/UCMM mill): The intermediate roll is used to distribute rolling force and improve plate shape.

HC/HCM rolling mill: The intermediate roll can move laterally in the axial direction to improve rolling accuracy.

Nonferrous metal rolling (copper, aluminum): higher requirements are placed on the corrosion resistance and wear resistance of the bearing seat.

Material selection for the bearing seat of the intermediate roller on the transmission side of the copper cold rolling mill

1. Material of bearing seat body

High strength cast iron/steel casting:

QT500-7 ductile iron: combines toughness and strength, with low cost.

ZG35CrMo alloy cast steel: resistant to impact and fatigue, used for heavy-duty rolling mills.

Forged steel:

42CrMo/34CrNiMo6: Improved density through forging, used for high-end rolling mills.

2. Wear resistant/friction reducing component materials

Copper alloy lining plate/bearing shell:

ZCuSn10Pb10 (tin bronze): High wear resistance, used for bearing mating surfaces.

ZCuAl10Fe3 (aluminum bronze): better corrosion resistance, suitable for rolling fluid environment.

compound material:

PTFE coated or embedded self-lubricating bearings reduce friction.

3. Material selection criteria

The magnitude of rolling force (the intermediate roll usually bears a large alternating load).

Do you need axial movement function (sliding surface requires low friction material).

Corrosive environment (such as the chemical reaction between copper powder and coolant during copper rolling).

Cold Rolling Mill Machine Bearing Chock is one of GW precision key products.

GW precision use computer process program for all production process for rolling mill bearing seat bending roll block and other products, which will make sure th process plan be arranged reasonably and final products quality be best controlled.

GW precision have got more than 31 patents in the developing period and will continuously focus on innovation to best serve our customers .

Start your day off right by reaching out to GW Precision Technology Co.,Ltd for any Cold Rolling Mill Machine Of The Transimit Side Intermediate Roller Bearing Block .

guangwei@gwspool.com or +86-379-64593276