Casting Steel Spool Used In Copper Strip Rolling Mill Machine Of Non-ferrous Industry

GW precision has 80% CNC machine tools, effectively improve the processing capacity and level of processing.

In common specifications, we have outer diameter ∮665 ∮609 ∮588 ∮572 ∮565 ∮562 ∮560 ∮552 ∮540 ∮482, length from 1000mm to 3000mm, and inner diameter is not limited

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Casting Steel Spool Used In Copper Strip Rolling Mill Machine Of Non-ferrous Industry

Casting sleeve material | specification |

35CrMoV | 665*605*1900 |

GW precision adopts advanced smelting and casting technology, with the equipment has accurate inspection to ensure the chemical composition of the casting sleeve material is reliable and accurate, also has the same characteristics. Centrifugal casting sleeve is adopted to guarantee the inner and outer surface of the casting sleeve is free from defects such as cracks, slag inclusion, pores and sand holes. Adopt mature heat treatment technology to ensure the mechanical properties of casting sleeve.

Key feature supplement:

1、High temperature performance:

Maintaining high strength at 500-600 ° C, suitable for high-temperature conditions.

2、Wear resistance:

Vanadium carbide (VC) and chromium carbide (Cr ₇ C ∝) provide excellent wear resistance.

3、Thermal fatigue resistance:

High thermal conductivity and toughness reduce the risk of thermal stress cracking

Heat treatment strengthening

Quenching and tempering treatment:

Quenching (850 ℃ oil cooling)+high temperature tempering (550 ℃ × 4h), hardness HRC28-32 (core toughness guarantee).

Surface strengthening:

Ion nitriding: surface hardness ≥ HV900, infiltration layer 0.3-0.5mm (wear resistance increased by 5 times);

Alternatively, laser quenching can be used to selectively harden the contact surface (hardness HRC55-60, deformation<0.03mm).

35CrMoV centrifugal cast steel sleeve is suitable for heavy-duty and high-precision scenarios of high-end cold rolling mills due to its high strength, high wear resistance, and fatigue resistance. The core of its manufacturing lies in:

Centrifugal casting ensures compactness;

Optimizing strength and toughness through quenching and tempering heat treatment;

Precision machining ensures precise fit.

By customizing designs such as gradient hardness and composite structures, the service life can be further extended and the maintenance cost of the rolling mill can be reduced.

Description of heat treatment of casting steel sleeve

We will conduct heat treatment strictly for casting steel sleeve which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every product to achieve the best condition and customers’ good results.

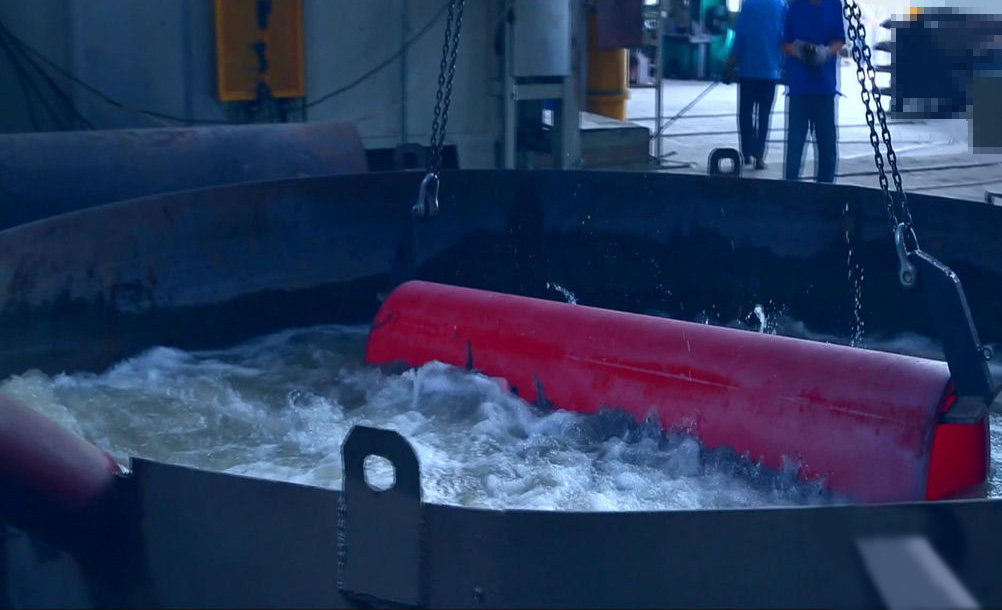

Dynamic Balancing Test

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of casting sleeve products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

We have excellent packaging team and mature packaging technology.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!