Casting Steel Spool Of Aluminum Foil Mill Machine Tested By Dynamic Balancing Machine

Application:Steel spool is widely used in aluminum foil, aluminum plate, stainless steel foil belt and other industries of foil, plate, tape rolling. Therefore, our company has a strict requirement to concentricity of sleeve, dynamic balance and other requirements.

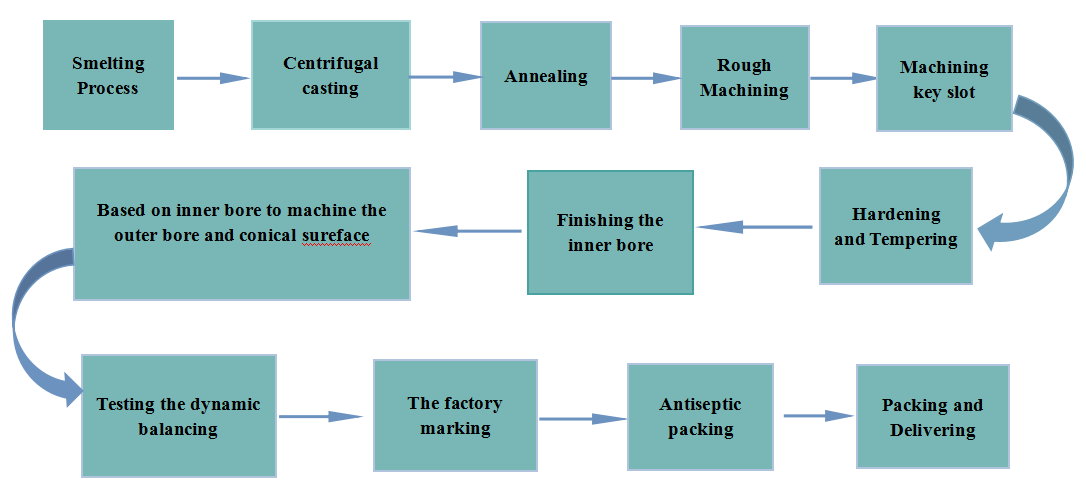

Technology:The steel spool blank of our company is obtained by centrifugal casting.

Advantage of GW steel spool:

1.The company has our own professional processing of the design, develop and manufacture, also have proven machining technique.

2.Our company has a well-developed management system. Meanwhile, our employees are highly qualified and skilled.

3.The company has a perfect management system of the guarantee of the after-sales service.

4.Our customers are already spread all over China, and our annual production capacity of the sleeve is 4000 sets per year.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Casting Steel Spool Of Aluminum Foil Mill Machine Tested By Dynamic Balancing Machine

Steel spool material | Specification |

ZG310-570 | 565*505*1600 |

Steel Spool Produce Process

ZG310-570 is a medium carbon cast steel material with high strength and good casting performance, suitable for sleeve components in aluminum foil rolling mills that can withstand high loads and high speeds.

Application scenario of aluminum foil rolling mill cast steel sleeve tested by dynamic balancing machine

Core functions

Supporting rollers: bear radial and axial loads during high-speed rolling process (500~1500 rpm);

Transmission torque: Drive the rolling mill to achieve precision rolling of aluminum foil (thickness tolerance ± 1-3 μ m);

Dynamic stability: Through dynamic balance correction, ensure minimal vibration during high-speed operation (ISO G2.5 standard).

Typical operating conditions

High speed rotation: working speed of 800~1200 rpm (precision rolling mill);

Medium high temperature: The temperature in the rolling zone is 150-300 ℃, and thermal fatigue resistance is required;

Lubrication environment: In contact with rolling oil, it needs to be corrosion-resistant and wear-resistant.

Applicable equipment

Four roll/six roll aluminum foil rolling mill (such as Sendzimir rolling mill);

Rough rolling or precision rolling stands, especially in high load rolling sections.

Chemical composition (mass percentage) of ZG310-570 Steel Spool:

Execution standard: According to GB/T 11352-2009 (General Engineering Cast Carbon Steel Parts)

Range of Element Content (%) Function

Carbon (C) 0.25-0.35 improves strength and hardness, dominates mechanical properties

Deoxygenation of silicon (Si) 0.20-0.45 improves casting fluidity

Manganese (Mn) 0.50-0.80 refines grain size, improves hardenability and toughness

Phosphorus (P) ≤ 0.035 impurities (strictly controlled to prevent cold brittleness)

Sulfur (S) ≤ 0.035 impurities (prone to forming sulfide inclusions, affecting toughness)

Since the very beginning of production, the company formed the principle of top-ranking products, quality and service. with strict quality inspection and technology control for our Steel spool products. GW precision steel spool products are popular among domestic aluminium processing plants and some abroad companies in Europe and India.

Basing on the experiments of decade years, we had designed the horizontal automatic boring machine independently and received the state certification of invention. By doing so, we manage to enhance the quality of processing the inner hole, releasing the labor tension and improving the efficiency.

During the process of outer hole, we use the advanced CNC automatic machine tool to replace the old one. This allows company to improve the quality and efficiency, releasing the labor tension.

Thanks to the surrounding environmental advantages of Luoyang, our company receives many help and support in material, hear treatment, processing and technology. Learning from each company of aluminium industry, company has developed the products, fulfilling the demands of customers.

These are the advantages that make us reach the top in steel spool production. Our orders have also accounted large proportion in this industry. All the staffs will learn the advanced management thought to better serve our customers.

If you want to know more information about our steel spool products, pls contact us anytime!

guangwei@gwspool.com

.