Aluminum foil rolling mill cast steel reel

GW precision has a perfect management system of the guarantee of the after-sales service.

Our customers are already spread all over China, and our annual production capacity of the steel sleeve is 4000 pcs per year.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Aluminum foil rolling mill cast steel reel

The steel reel material is ZG25Cr2Mo1V, and the specification of the steel reel is Φ546*Φ504*2050.

ZG25Cr2Mo1V cast steel sleeve for aluminum foil rolling mill is a high-performance cast steel component mainly used in high load, high-precision aluminum foil rolling scenarios. Compared with 304 stainless steel sleeve, it has higher strength, wear resistance and high temperature stability, and is suitable for more demanding working conditions.

Material characteristics of cast steel sleeve for aluminum foil rolling mill (ZG25Cr2Mo1V)

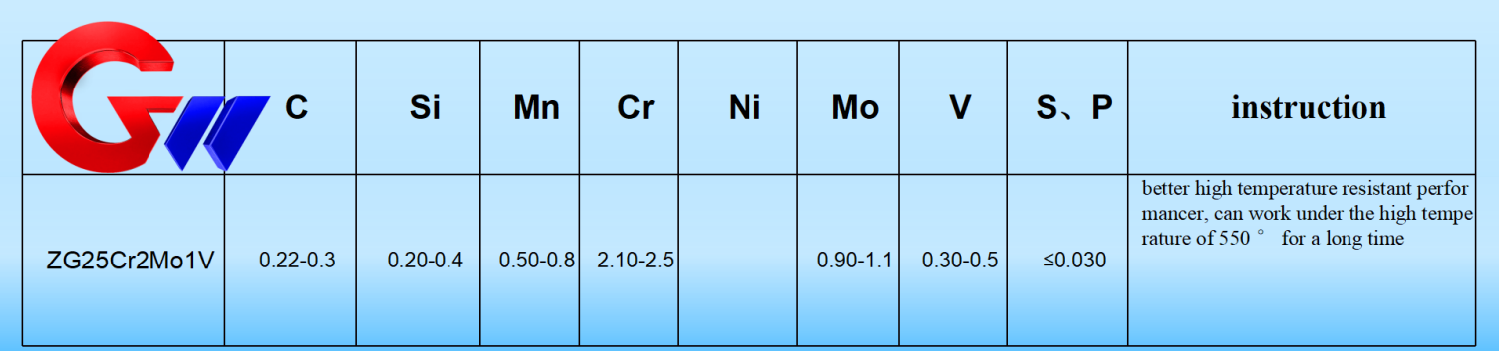

Chemical composition (typical values)

Element C Cr Mo V Si Mn P/S

Content 0.22~0.28% 2.0~2.5% 0.8~1.2% 0.2~0.4% ≤ 0.6% ≤ 0.8% ≤ 0.03%

Material advantages

High strength (tensile strength ≥ 800 MPa, yield strength ≥ 600 MPa);

Excellent high-temperature performance (Mo, V increase thermal strength, resistance to tempering softening);

Good wear resistance (Cr, Mo form hard carbides);

Excellent casting performance (ZG stands for cast steel, suitable for complex structures).

Heat treatment process of cast steel sleeve for aluminum foil rolling mill

ZG25Cr2Mo1V belongs to low-alloy high-strength cast steel, and its microstructure and properties need to be optimized through heat treatment. The key steps are as follows:

(1) Annealing (eliminating casting stress)

Process: Keep at 850~900 ℃ for 2-4 hours, cool in the furnace to 600 ℃ and then air cool;

Objective: To achieve uniform organization, reduce residual stress, and improve machinability.

(2) Quenching+tempering (quenching and tempering treatment)

quench:

Temperature: 920-950 ℃ (austenitization), insulation time calculated based on wall thickness (1h/25mm);

Cooling method: oil quenching (for small parts) or polymer quenching (for large parts, to reduce deformation).

Tempering:

Temperature: 550~650 ℃ (adjusted according to hardness requirements), insulation for 2-4 hours;

Target hardness: HRC 28-35 (balancing strength and toughness).

(3) Surface strengthening (optional)

Induction hardening: locally hardening the shaft neck to HRC 45~50 to improve wear resistance;

Nitriding treatment: Gas nitriding (500 ℃ × 20h), surface hardness ≥ HV 800.

ZG25Cr2Mo1V cast steel sleeve can meet the high load and high-precision requirements of aluminum foil rolling mills through precision casting, quenching and tempering heat treatment, and dynamic balance correction. Its manufacturing cycle is about 6-8 weeks (including heat treatment and testing), and its lifespan is usually 5-8 years (depending on maintenance and operating conditions). Compared to 304 stainless steel sleeves, it is more suitable for heavy-duty rolling mills and high-temperature high load environments, but the cost is higher and strict quality control is required.

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of steel reel products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

We have excellent packaging team and mature packaging technology.

Our steel reel products are widely recognized and trusted by users and can meet continuously changing economic and social needs.