Intermediate Roller Bearing Chock Of Hot Mill Machine

GW precision Advantages:

high-precision intelligent CNC manufacturing equipment, high-tech staff, mature processing system, strict quality inspection process, excellent production management process, is the guarantee of high-quality products.

In order to better ensure the quality of products, in addition to the regular size inspection, the company bought a high-precision mobile bridge type three-position standard measuring machine, the detection accuracy up to 2 micron level, to ensure the absolute inspection basis of various parts size and behavior tolerance inspection.

- Guangwei Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Intermediate Roller Bearing Chock Of Hot Mill Machine

GW Precision manufacture all kinds of mill bearing blocks and other mill precision parts.

Intermediate Roll Bearing Chock could support mill work roll ,intermediate roll, back-up rolls of different rolling mill during working.

Product Material

working roll (forgings):45 steel,40Cr,42CrMo

support roll (castings): zg310-570, zg270-500.

GW precision has formed a set of mature mechanical processing technology for the production of Intermediate Roll Bearing Chock through the accumulation of long-term experience:

Technology and Process Equipment

Scientific and reasonable arrangement of technological processing improves the accuracy, rationality and stability of product processing, and guarantees the quality.

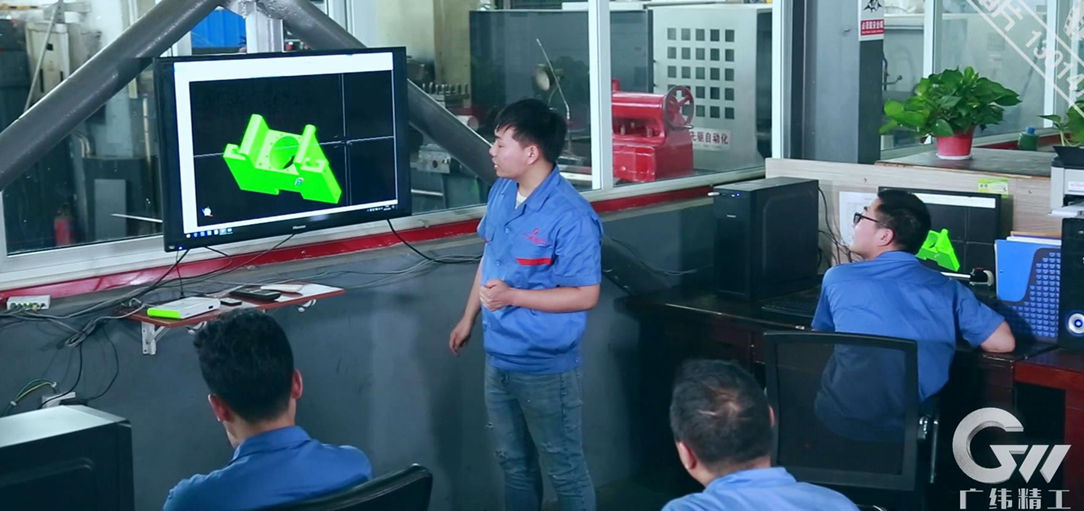

CNC machining programming

Programmers use the PC simulation processing to run program, optimizating processing lines and reasonable arranging the processing tools, so that the processing of the workpiece more accurate with neat and beautiful knife lines.

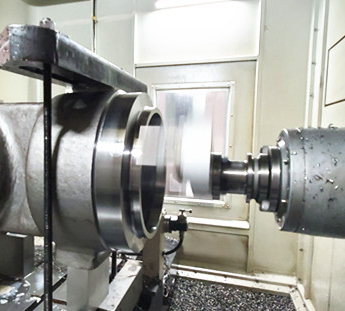

High-precision processing equipment

CNC horizontal machining center, CNC vertical machining center, five axis comprehensive machining center and other high-precision processing equipment ensure the accuracy of product processing size, also ensure that the complex structure of the workpiece can be smoothly and accurately processed.

Quality Control

We have strictly inspection process from blank, flaw detection, heat treatment to the production process.

Strict inspection and testing procedures are our quality assurance. Each Intermediate Roll Bearing Chock will provide a complete set of chemical composition analysis report, heat treatment report, flaw detection report, dimensional tolerance, shape and position tolerance inspection report , all of which are traceable.