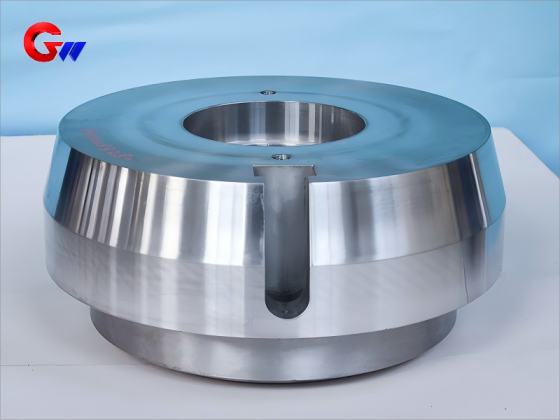

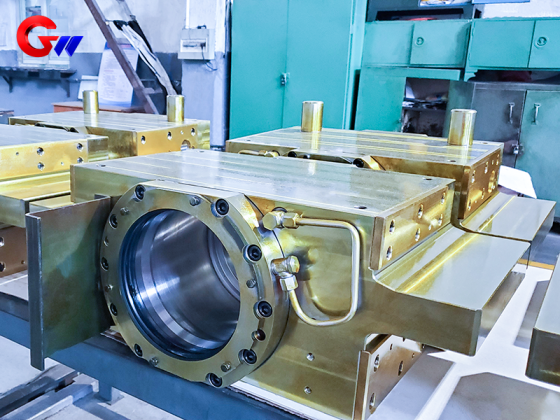

Working roll bearing seat on the operating side of the hot rolling mill

The core function and working condition requirements of the working roll bearing seat on the operating side of the hot rolling mill

Core functions

Roll positioning and support: bear the radial load (1500-4000kN on one side) and axial force (≤ 10% radial force) of the work roll.

Quick roll change interface: Integrated hydraulic locking mechanism (pressure 20-25MPa), roll change time ≤ 15 minutes.

Thermal deformation compensation: At a rolling temperature of 300-600 ℃, the axial thermal expansion gap is reserved at 0.1-0.15mm/100 ℃.

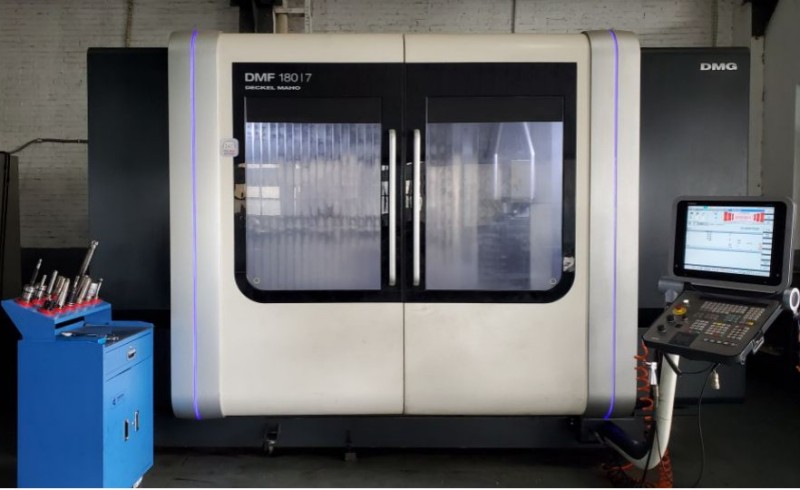

- Guangwei Manufacturing Precision

- Henan,Luoyang

- Contractual Stipulation

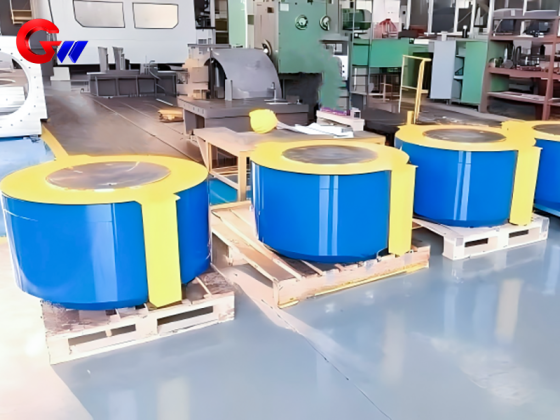

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Working roll bearing seat on the operating side of the hot rolling mill

Compatible models

Four roll hot rolling mill: strip width 800-2200mm, rolling speed ≤ 12m/s.

Reversible roughing mill: rolling force fluctuation ± 25%, impact load frequency ≥ 5 times/minute.

Specification for Material and Heat Treatment of Working Roll Bearing Seat on the Operating Side of Hot Rolling Mill

Main material

Cast steel grade: ZG35CrNiMo (optimized composition)

|Element | C 0.32-0.38 | Cr 0.8-1.2 | Ni 1.0-1.5 | Mo 0.2-0.4|

Performance characteristics:

High temperature yield strength (σ ₀. ₂ ≥ 550MPa at 500 ℃);

Low temperature impact energy (-20 ℃ AKV ≥ 50J).

Key component materials

Component material heat treatment surface treatment

ZG35CrNiMo quenched and tempered bearing seat body+stress relief shot peening strengthening (Sa2.5)

Wear resistant lining plate 42CrMo4 induction quenched hard chromium plating (30-50 μ m)

Sealing component 316L stainless steel solid solution treatment electrolytic polishing

Heat treatment process

Quenching: 850 ± 10 ℃ × 4h (oil cooling, cooling rate ≥ 80 ℃/s);

Tempering: 580 ± 10 ℃ × 6h (air cooling, hardness control HB 280-320);

Cryogenic treatment:- 80 ℃ for 2 hours (to improve dimensional stability).

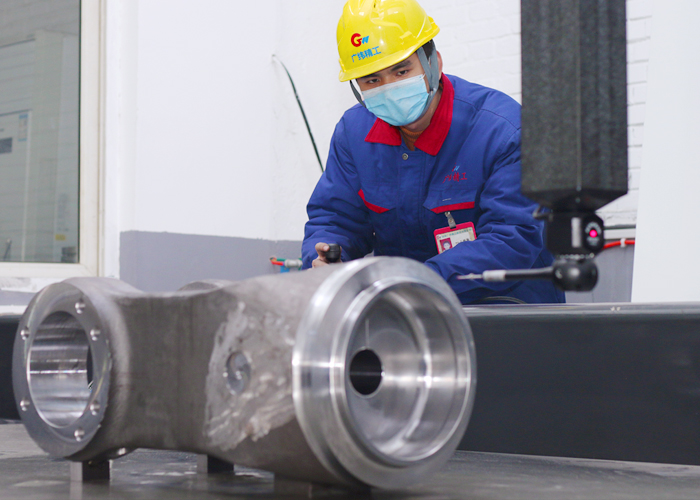

Mechanical processing and assembly accuracy of the working roll bearing seat on the operating side of the hot rolling mill

Critical dimensional tolerances

Project tolerance testing methods

Bearing hole diameter (Φ) H6 level (± 0.015mm) pneumatic meter+three coordinate system

Installation surface flatness ≤ 0.02mm/m electronic level

Hydraulic oil circuit cross hole chamfer R0.5 ± 0.1mm industrial endoscope

Assembly requirements

Bearing preload force: Axial preload of tapered roller bearings is 0.05-0.08mm (measured by a dial gauge);

Sealing clearance: radial 0.3-0.5mm (labyrinth seal), axial 1.0-1.2mm.

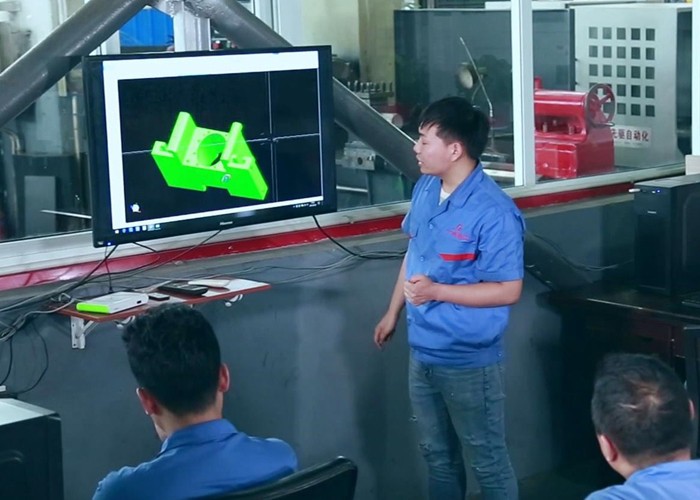

The above advantages of our company in the production of bearing housing make our company in the advanced position in the production of bearing block products domestically.production orders in the industry leading. The staff of the company will learn the advanced management ideas of the same industry in the future production and processing, so that the company can better serve customers and grow together with customers.

Packing

Start your day off right by reaching out to Luoyang Guangwei Precision Manufacturing Technology Ltd. for any Hot Rolling Mill Machine Of The Operate Side Work Roller Bearing Block spindle repair needs you may have.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!