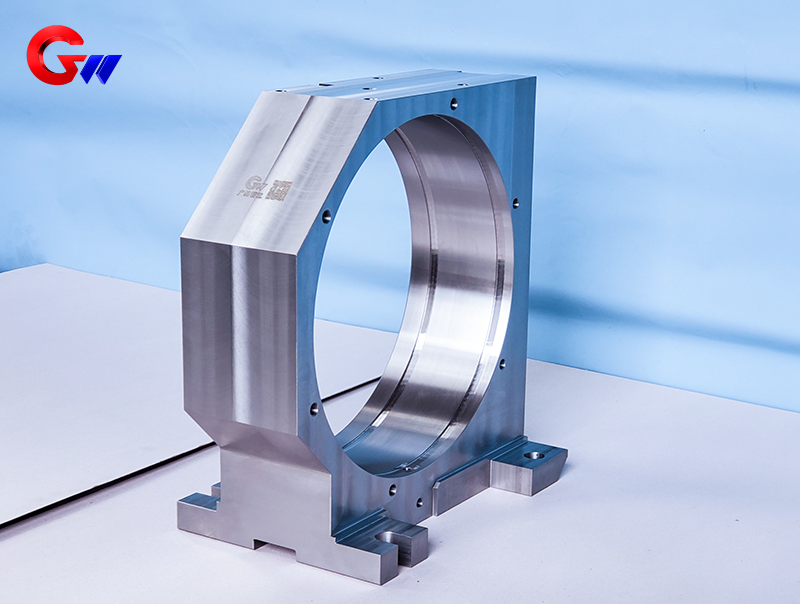

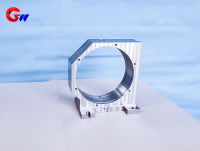

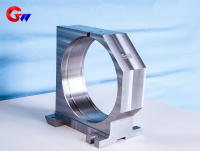

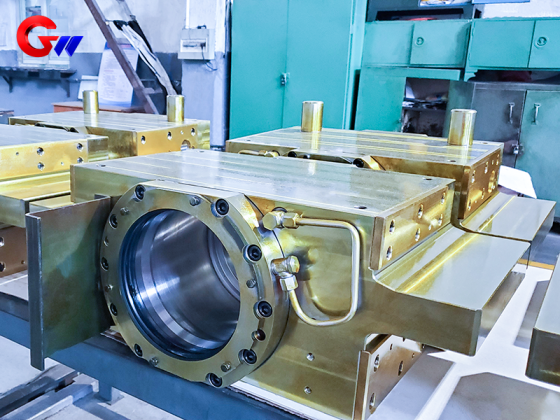

Cold Rolling Mill Drive Side Work Shaft Block

Where there is a bearing, there must be a support point. The inner support point of the bearing is the shaft, while the outer support is the Drive Side Work Roller Shaft Block.

The type is Drive Side Work Roller Shaft Block of mill work roll intermediate roll support roll, and can also accept other non-standard customizing from customers.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity 1000 pieces

- Information

Cold Rolling Mill Drive Side Work Roll Shaft Block

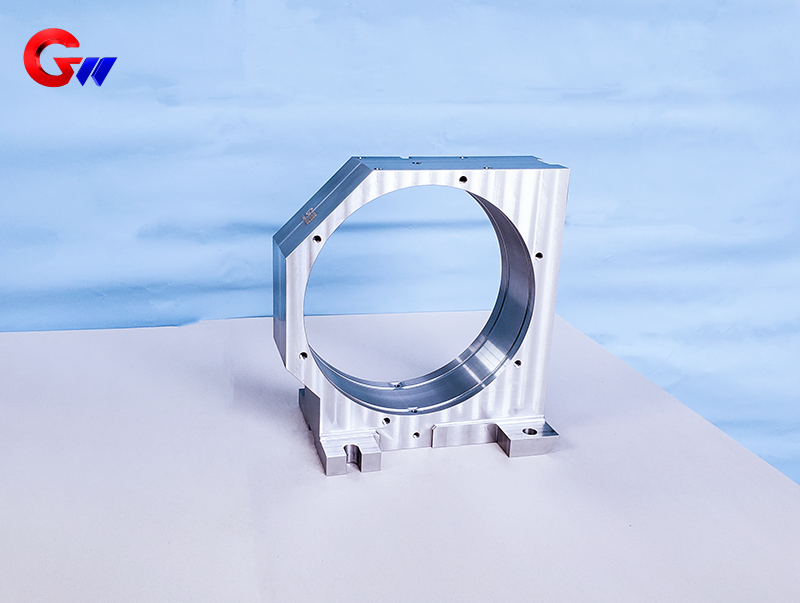

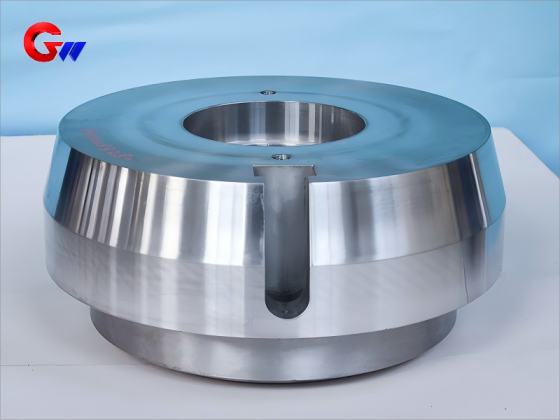

The shaft block of the working roll on the transmission side of the cold rolling mill is one of the core components of the rolling mill, used to support the working roll, transmit rolling force, and ensure the precise positioning and stable operation of the rolling roll. The working environment requires high rigidity, high wear resistance, and fatigue resistance.

Application scenarios of the working roll shaft block on the transmission side of the cold rolling mill

Cold rolled strip mill

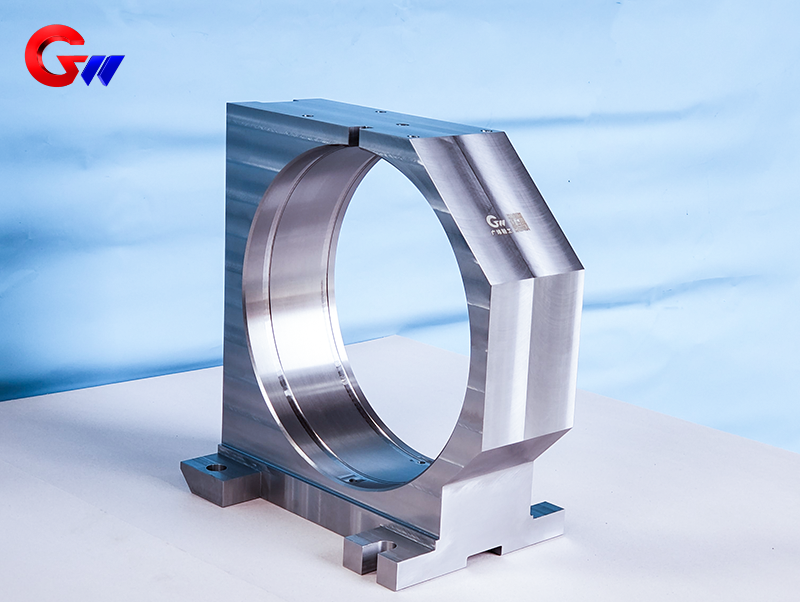

Suitable for high-speed (10-30m/s) and high-precision (plate thickness tolerance ± 0.01mm) cold rolling production lines, such as stainless steel, silicon steel, automotive plates, etc.

To withstand high radial loads (100-500 tons) and axial impacts, it is necessary to ensure the stable operation of bearings (such as four row tapered roller bearings).

Characteristics of working conditions

High stiffness requirement: to prevent elastic deformation caused by rolling force from affecting the shape of the plate.

Wear resistance: The mating surface between the inner hole of the bearing seat and the outer ring of the bearing should be resistant to micro motion wear.

Fatigue resistance: It is necessary to avoid crack initiation under alternating loads (the service life is usually required to be ≥ 10 years).

Material selection for the shaft block of the working roll on the transmission side of the cold rolling mill

Common materials:

Cast steel: ZG270-500, ZG35CrMo (low-cost, suitable for small and medium-sized rolling mills).

Forged steel: 35CrMoV, 42CrMo (high-strength, used for heavy-duty rolling mills).

High end application: Adopting a composite structure of alloy cast iron (such as QT600-3) and wear-resistant lining plate (Hardox 500).

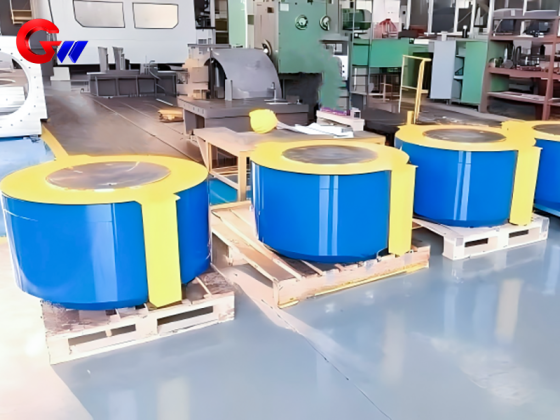

Guangwei precision technology Co.,ltd locates in western district of luoyang city, next to the Henan Diesel plant which is one of ten greatest plant during the First Five-year Plan in Henan province.

Drive Side Work Roller Shaft Blocks are one of our key products.

We have good understanding in the process of supporting Drive Side Work Roller Shaft Block and have formed quality control system to handle with the problems during the processing.

In order to control final inspection procedure, we purchased a high-precision mobile bridge type coordinate measuring machine.With inspecting the accuracy detection of CMM, our quality of the bearing block could guarantee and being improved much better.

If any Drive Side Work Roller Shaft Block you may need, just reach to Guangwei Precision Technology Co., Ltd.

guangwei@gwspool.com or +86-379-64593276