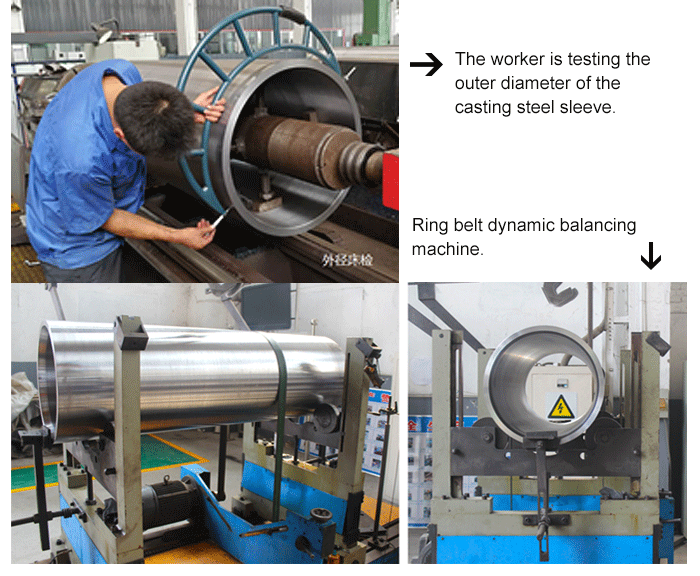

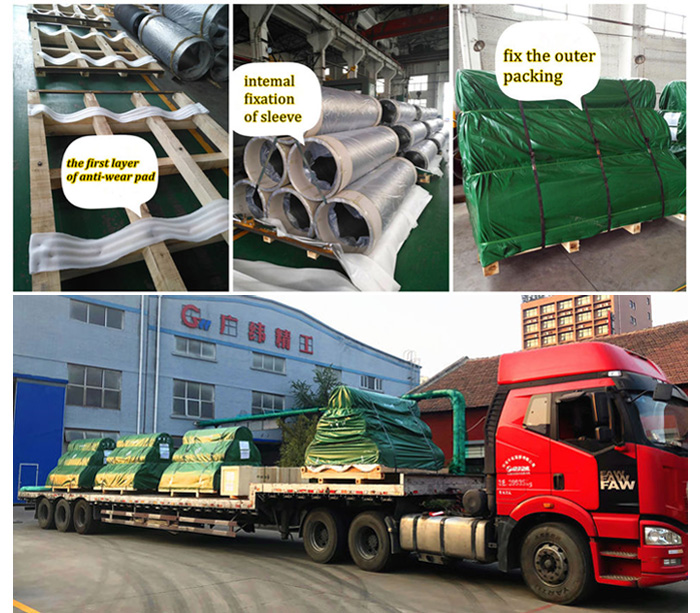

Casting Steel Spool Of Aluminum Strip Mill Tested By Dynamic Balancing Machine

Application:Sleeve is widely used in aluminum foil, aluminum plate, stainless steel foil belt and other industries of foil, plate, tape rolling. Therefore, our company has a strict requirement to concentricity of sleeve, dynamic balance and other requirements.

Technology:The sleeve blank of our company is obtained by centrifugal casting.

GW Advantage:

1.The company has our own professional processing of the design, develop and manufacture, also have proven machining technique.

2.Our company has a well-developed management system. Meanwhile, our employees are highly qualified and skilled.

3.The company has a perfect management system of the guarantee of the after-sales service.

4.Our customers are already spread all over China, and our annual production capacity of the sleeve is 4000 sets per year.

- Guangwei Manufacturing Precision

- Henan,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Casting Steel Spool Of Aluminum Strip Mill Tested By Dynamic Balancing Machine

Materials

| Sleeve Material | Specification |

| 35NiCrMo | 565*505*1700 |

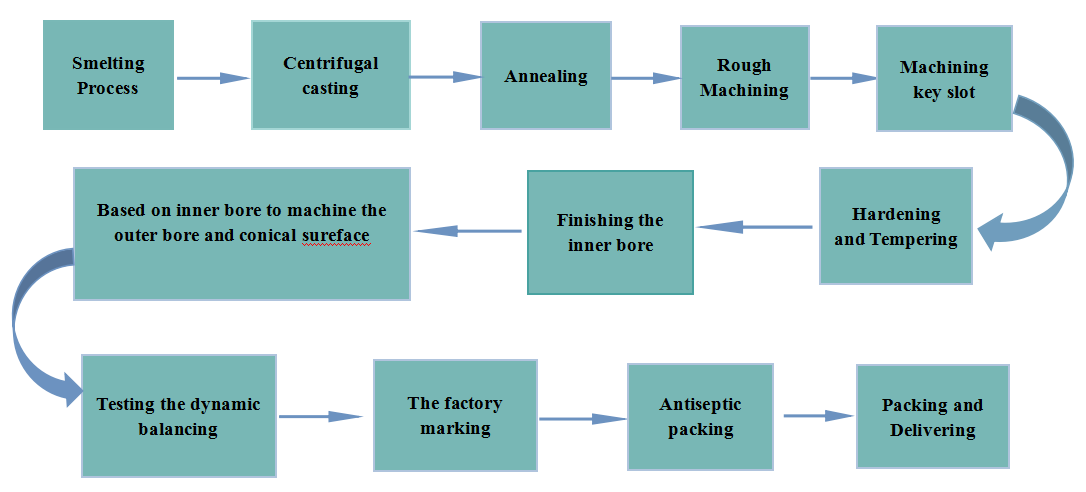

Product Process

1、Adopts advanced smelting and casting technology, with the equipment has accurate inspection to ensure the chemical composition of the sleeve material is reliable and accurate, also has the same characteristics.

2、Centrifugal casting is adopted to guarantee the inner and outer surface of the sleeve is free from defects such as cracks, slag inclusion, pores and sand holes.

3、Adopt mature heat treatment technology to ensure the mechanical properties of steel sleeve.

Description of heat treatment of steel sleeve

We will conduct heat treatment strictly for steel sleeve which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every product to achieve the best condition and customers'good results.

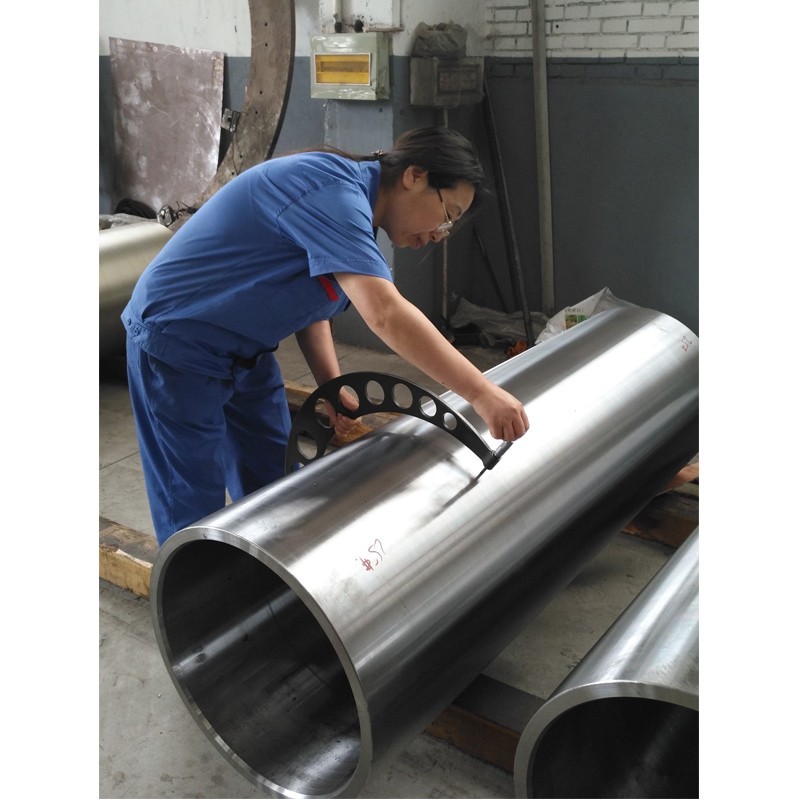

The workblank of spools will be processing on the hole drilling machine, which was developed by our company. In the boring machine, the sleeve blank can be adjusted to concentric of both the front and rear ends of the aperture, so as to achieve smooth cutting and improve machining accuracy. In the cutting process, the workpiece is fixed without rotating, and the way that tool shaft rotates to cut the inner hole avoid the error of taper or other shapes. Smooth chip removal during the cutting process allowsto improve the surface smoothness and not easy to scratch the processed surface.

After the hole drilling processing is completed, the spool will be processed during the Double self-centering nc machine tool, in double (this machine tool is developed after many years of experience in research of high precision large size double self-centering nc machine tool). On both ends of the sleeve are the hydraulic support chucks that can quickly locate on both ends of the inner hole and ensure the concentricity on both ends of the inner hole are within the allowed tolerance; The machine tool starts to process the outer circle and ensures that the concentricity of the inner and outer circle is within the allowable tolerance range. The conical circles of inner holes at both ends are also concentric within the permissible tolerance.

Inspection and testing

Strict inspection and testing procedures are our quality assurance. Each sleeve has a complete set of chemical composition analysis report, heat treatment report, material mechanical analysis report, dimensional tolerance, shape and position tolerance inspection report, all of which have traceability.