Dedicated Stainless Steel Sleeve Of Colding Mill Machine

The outstanding advantages of the special sleeve for 304 stainless steel cold rolling mill

Super strong corrosion resistance

Compared to carbon steel sleeves, their lifespan is increased by 5-8 times in emulsion environments (usually up to 10 years or more).

Surface quality assurance

No risk of coating detachment, avoiding chromium contamination issues with traditional chrome plated sleeves (compliant with FDA/ROHS).

Easy to maintain

It can be fully acid washed and passivated (HNO ∝+HF solution) to restore the surface state without the need for regular replacement.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Dedicated Stainless Steel Sleeve Of Colding Mill Machine

Core application scenarios of special sleeves for 304 stainless steel cold rolling mills

Typical operating conditions

High cleanliness rolling: used in fields sensitive to iron ion pollution, such as food grade stainless steel sheets (0.2-3mm) and medical equipment steel.

Corrosion environment: high humidity/chemical corrosion scenarios such as acid pickling line supporting rolling mills and coastal factories.

Low temperature cooling: In conjunction with an emulsion cooling system (pH 6-8), long-term contact with the coolant will result in no corrosion.

GWspool Main Products

steel Spools,all kinds of mill bearing blocks, bending blocks and other mill precision parts, rolling mill bearing blocks are our key products.

Product Information

| Sleeve Material | Specification |

| 304 stainless steel | 355*305*1000 |

Key Performance Characteristics of 304 Stainless Steel Cold Rolling Mill Special Sleeve

Material characteristics

Composition optimization (ASTM A240 standard):

|Element | Cr 18-20% | Ni 8-10.5% | C ≤ 0.08% | Other (Mn/Si, etc.) ≤ 2%|

Austenitic structure: non-magnetic, may produce weak magnetism (≤ 1.05 μ) after cold processing.

Corrosion resistance:

No red rust after 5% salt spray test for ≥ 500 hours.

Resistant to corrosion by organic acids such as nitric acid (≤ 65% concentration) and acetic acid.

Mechanical Properties of 304 Stainless Steel Cold Rolling Mill Special Sleeve (After Solution Treatment)

Special treatment effect on typical values of indicators

Tensile strength ≥ 515 MPa can reach 1200 MPa after cold rolling

Yield strength ≥ 205 MPa after cold work hardening ≥ 800 MPa

Hardness HB 170-200: HB ↑ 30 after surface shot peening

Elongation rate ≥ 40% ensures the ability to resist impact deformation

Description of heat treatment of stainless steel sleeve

We will conduct heat treatment strictly for stainless steel sleeve which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every stainless steel sleeve product to achieve the best condition and customers’ good results.

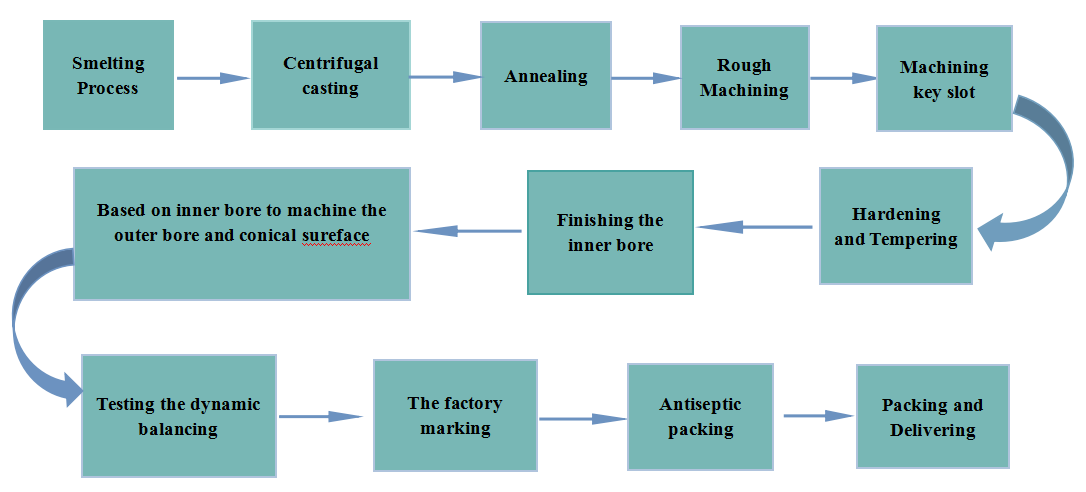

(product process)

We used our independent dedicated device-hole drilling machine which is researched and developed by ourselves, it also obtain the national patent. The machine is provided with good rigid, no returning clamp and machine and high accuracy on the processing of machining. Through continuous improvement, our company formed a integrated processing technic system to ensure concentricity, cylindricity, degree of symmetry and dynamic balance of the stainless steel sleeve. Specific accuracy tolerance and geometric accuracy tolerance is strictly according to the customers’ requires.