What is the function of CMM detection?

2021-10-27 16:00Coordinate measuring instrument (CMM) is a kind of high efficiency, new type and high precision measuring instrument. CMM is widely used in mold, gauge, hardware, electronics, machinery, auto parts, aerospace and other industries in the inspection and measurement of workpiece. CMM can detect the size, shape and position of the workpiece; For all kinds of parallelism, verticality, symmetry, concentricity detection; Surface data can be obtained by scanning the surface; The test data can be returned to the CAD system through the test equipment to correct the processing and production of the product.

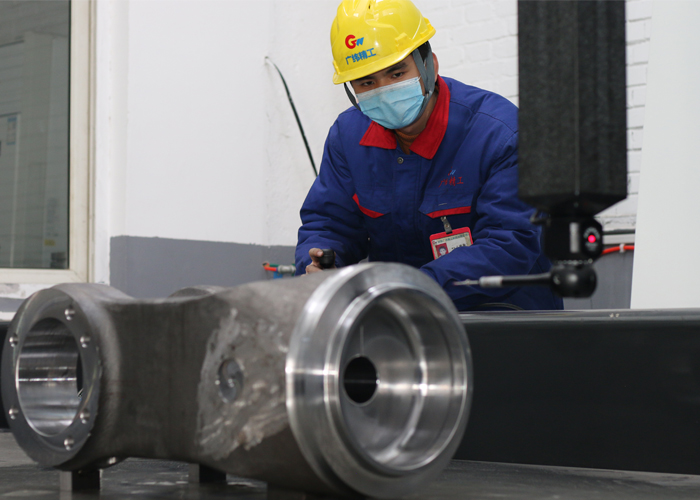

In order to better ensure the quality of products, in addition to the regular size inspection, we bought a high-precision mobile bridge type CMM measuring machine. The detection accuracy up to 2 micron level to ensure the absolute inspection basis of various parts size and behavior tolerance inspection.

Measurement system with high stability is capable of quickly and efficiently completing the common inspection needs, and greatly improving the inspection efficiency.

What is the function of CMM detection?

First, it solves the measurement of complex shapes. CMM can measure and evaluate basic geometrical elements such as straightness, flatness, cylindricity, conicity, coaxiality, concentricity, axial runout and radial runout with high precision. In addition, CMM can also solve the measurement of complex shape surface profile size, such as box parts aperture and hole location, blade and gear, automobile and aircraft profile size detection.

Second, improve the measurement accuracy. Advanced all-aluminum technology is adopted, and hard anodized aviation aluminum alloy is used on the surface of the beam and Z axis, which reduces the mass of the moving parts and the inertia of the measuring machine at high speed to ensure high speed and precision. The three-axis guide rail of CMM adopts high-precision, self-cleaning air bearing, which is more stable in the measurement process. The x-direction of the CMM adopts the patented technology of precision 60-degree triangular beam, which has a lower center of gravity, the best mass-rigidity ratio and more reliable movement than the rectangular beam. The Y-axis of CMM adopts integral dovetail guide rail, which can reduce the weight of the machine and effectively eliminate the moving torsion pendulum, thus ensuring the measuring accuracy and stability. In the Z direction of the CMM, the patented pneumatic balance technology is adopted, and the flexible suspension system is adopted, which avoids the interference between the axial motion and the transmission system, and improves the stability and measurement accuracy of the CMM.

Third, improve the measurement efficiency. With the development of measuring machine automation, many measuring processes can be handed to the measuring machine to complete. Three coordinates measuring instrument can realize automatic measurement artifacts, as long as the work on stage, being measured by three coordinates measuring instrument of automatic measurement function, can be easily read out, accurate measurement of workpiece data information, the implementation of measured object automatic measurement and report output, saving time, accuracy is greatly improved, thus greatly improve the efficiency of measurement.