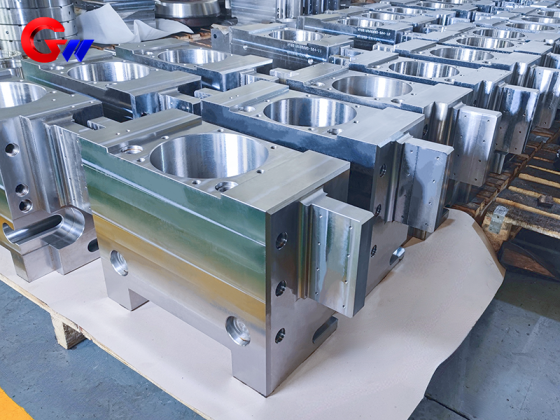

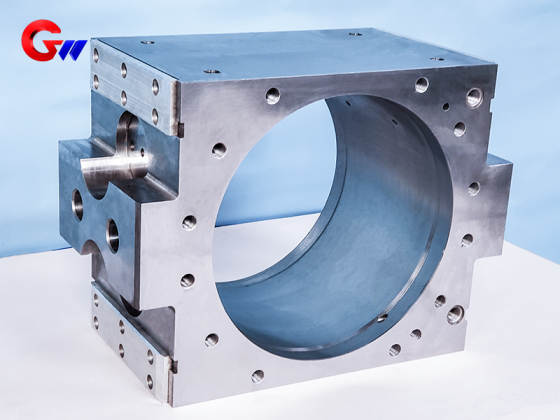

Rolling Mill Bearing Block Of Working Roller Of Cold Mill Machine

Our main products are all kinds of mill bearing blocks, bending blocks and other mill precision parts, rolling mill bearing blocks are our key products.

The type is the bearing seat of mill work roll intermediate roll support roll, and can also accept other non-standard customizing from customers.

Material:

support roll (castings): zg310-570

Function

1、Supporting function: Provide stable support for the rolling mill bearings, ensuring that the bearings can withstand tremendous rolling and impact forces during operation.

2、Positioning function: Ensure the accurate installation position of the bearing, so that the rolling mill can rotate in the correct position, thereby ensuring rolling accuracy.

3、Sealing function: prevent external dust, impurities, and cooling water from entering the interior of the bearing, which may affect the service life of the bearing.

- Guangwei Manufacturing Precision

- China,Luoyang

- Contractual Stipulation

- Information

Rolling Mill Bearing Block Of Working Roller Of Cold Mill Machine

GW precision technology co.ltd,. locates on the west side of the Henan Diesel plant, one of ten greatest plant during the First Five-year Plan in Henan province.

ZG310-570 is a medium carbon cast steel material with high strength, good casting performance, and machinability, suitable for heavy-duty components such as work roll bearings in cold rolling mills.

Application scenarios of bearing seats for working rolls and rolling mills in cold rolling mills

Core functions

Supporting work rolls: capable of withstanding high radial and axial forces during the rolling process (rolling forces can reach hundreds of tons);

Fixed bearings: Ensure stable operation of roller bearings, reduce vibration and eccentric load;

Transfer load: Disperse the rolling force to the frame to ensure rolling accuracy (strip thickness tolerance ± 1-3 μ m).

Typical operating conditions

High load: The cold rolling mill has high rolling pressure, and the bearing seat needs to withstand extremely high contact stress;

Low speed heavy load: The working speed is usually 50~300 rpm (cold rolling mill speed is low, but the load is large);

Lubrication environment: It needs to be compatible with the rolling mill lubrication system (such as grease or oil mist lubrication).

Applicable equipment

Four roll/six roll cold rolling mill (such as UC-MILL, Sengemir rolling mill);

Reversible cold rolling mill (such as single stand rolling mill);

High precision rolling mills (such as automotive plate and electrical steel rolling mills).

Heat treatment process for bearing seat of working roll mill in cold rolling mill

ZG310-570 cast steel bearing seat needs to optimize its mechanical properties through heat treatment. The main process is as follows:

(1) Annealing (eliminating casting stress)

Process: 850~900 ℃ × 4~6h, furnace cooled to 500 ℃ and then air cooled;

Objective: To achieve uniform organization, reduce residual stress, and improve machinability.

(2) Normalize (refine grain size)

Process: 880~920 ℃ × 2h, air-cooled;

Applicable scenario: When the strength requirement is not extremely high, it can replace quenching and tempering treatment.

(3) Quenching and tempering treatment (quenching+tempering, high strength requirement)

Quenching: 850~880 ℃ water quenching or oil quenching (depending on size);

Tempering: 550~600 ℃ × 2~4h, target hardness HB 220~280.

(4) Surface strengthening (optional)

Induction hardening: The bearing installation surface is locally hardened to HRC 45~50;

Nitriding treatment: Gas nitriding (500 ℃ × 20h), surface hardness ≥ HV 600.

Sealing structure

To prevent dust, impurities from entering and grease leakag,oil seals and labyrinth seals are commonly used.

Oil seal is a rubber or plastic product that seals by the contact between the lip and the shaft;

Maze seals use tortuous channels to prevent impurities and lubricating grease from entering and leaving, and are used in high sealing requirements and harsh environments.

fixture

Install the rolling mill bearing block on the mechanical equipment through a fixed device. The rolling mill bearing block connected by bolts has bolt holes and is fixed with bolts; The embedded rolling mill bearing block is directly embedded into the specific structure of the device, saving space and used for high-precision positioning equipment.