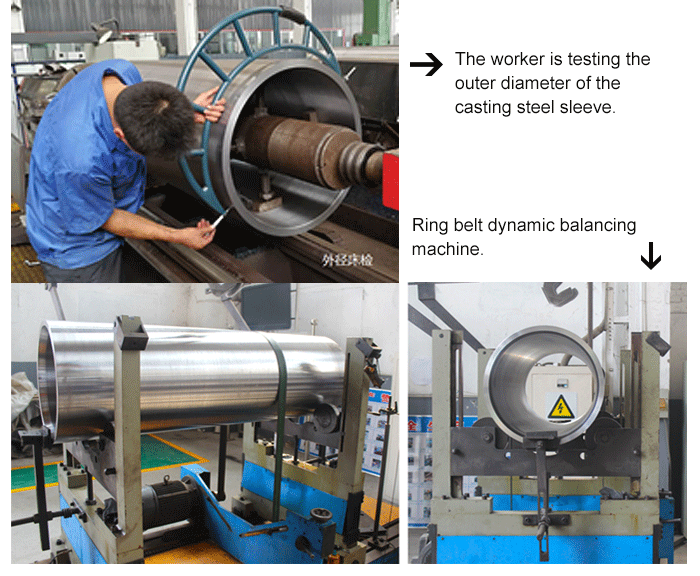

Aluminum strip rolling mill cast steel sleeve (dynamic balance inspection)

Core application scenarios of Aluminum strip rolling mill cast steel sleeve:

Suitable for aluminum strip mills with a rolling speed of 1200-2500m/min (thickness 0.1-2.0mm), residual unbalance ≤ 0.4g · cm/kg (G0.4 grade).

Typical models: Four roll/six roll cold rolling mill, Sengemir 20 roll rolling mill (used for battery foil, packaging foil).

Strict working condition requirements

Dynamic stability: Suppress high-frequency vibration (amplitude ≤ 0.8 μ m) during rolling of thin strips.

Thermal mechanical coupling: The instantaneous temperature in the rolling zone is 150-250 ° C, and it needs to resist alternating thermal stress.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Aluminum strip rolling mill cast steel sleeve (dynamic balance inspection)

| Sleeve Material | Specification |

| 35NiCrMo | 565*505*1700 |

Application of Aluminum Strip Rolling Mill Cast Steel Sleeve (Dynamic Balance Inspection)

Aluminum strip rolling machine dynamic balancing system

As a supporting component of the rolling mill, Aluminum strip rolling mill cast steel sleeve can withstand high speed, heavy load, and alternating stress, ensuring dynamic balance during the rolling process and improving the thickness uniformity and surface quality of aluminum strip.

Performance characteristics of Aluminum strip rolling mill cast steel sleeve

High strength and toughness

35NiCrMo is a low-alloy high-strength steel, and the Ni Cr Mo combination provides high tensile strength (≥ 850MPa) and good impact toughness, suitable for heavy-duty impact environments.

Excellent fatigue resistance

Alloy elements refine grain size, enhance fatigue resistance, and extend service life under alternating stress.

Wear resistance and surface hardness

The hardness of HRC 30-40 can be obtained through quenching and tempering (quenching+high-temperature tempering), and the surface can be further quenched or nitrided to enhance wear resistance.

high temperature resistance

Mo element improves tempering stability, with a working temperature of 400-500 ℃ (short-term), suitable for instantaneous high temperature during rolling process.

Good processability

The casting performance is superior to that of high alloy steel, and it is easy to form complex sleeve structures; Welding requires preheating (200-300 ℃) and post weld heat treatment to avoid cracking.

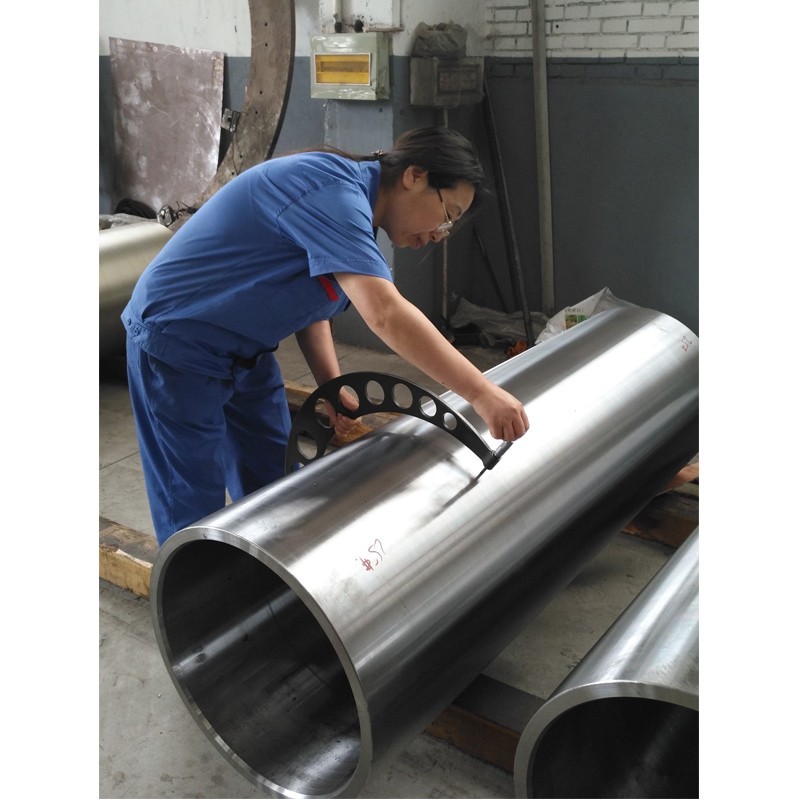

The workblank of aluminum strip rolling mill cast steel sleeve will be processing on the hole drilling machine, which was developed by our company. In the boring machine, the sleeve blank can be adjusted to concentric of both the front and rear ends of the aperture, so as to achieve smooth cutting and improve machining accuracy. In the cutting process, the workpiece is fixed without rotating, and the way that tool shaft rotates to cut the inner hole avoid the error of taper or other shapes. Smooth chip removal during the cutting process allowsto improve the surface smoothness and not easy to scratch the processed surface.

After the hole drilling processing is completed, the cast steel sleeve will be processed during the Double self-centering nc machine tool, in double (this machine tool is developed after many years of experience in research of high precision large size double self-centering nc machine tool). On both ends of the cast steel sleeve are the hydraulic support chucks that can quickly locate on both ends of the inner hole and ensure the concentricity on both ends of the inner hole are within the allowed tolerance; The machine tool starts to process the outer circle and ensures that the concentricity of the inner and outer circle is within the allowable tolerance range. The conical circles of inner holes at both ends are also concentric within the permissible tolerance.

Inspection and testing

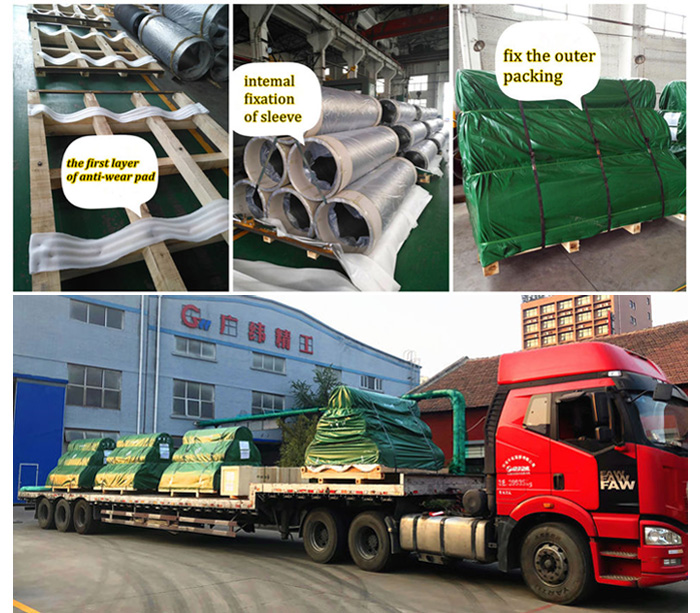

Strict inspection and testing procedures are our quality assurance. Each cast steel sleeve has a complete set of chemical composition analysis report, heat treatment report, material mechanical analysis report, dimensional tolerance, shape and position tolerance inspection report, all of which have traceability.